Energy Efficiency in Modern Coil Packing Lines

The heat is on: Steel producers face a 20% surge in energy costs while scrambling to meet strict decarbonization targets. Our outdated coil packing line guzzled electricity and hemorrhaged material—until automation transformed it into a lean, green productivity engine slashing waste by 40% and emissions by a fifth.

Modern coil packing lines achieve energy efficiency through integrated automation, precision material application, and smart energy management systems. Key strategies include sensor-guided wrapping reducing film usage by 30%, PLC-optimized machinery cutting electricity consumption 20%, and IoT-enabled monitoring eliminating compressed air leaks costing £13,000 annually. These technologies collectively lower operational costs while meeting sustainability benchmarks.

You’re not just fighting rising energy bills—you’re battling for market survival. What follows is the blueprint we used to conquer waste, empower workers, and future-proof our operations against volatile energy markets.

Where Untapped Energy Drains Hide in Your Packaging Line

That persistent hum? It’s the sound of money evaporating. Traditional coil packing harbors three silent killers: antiquated machines burning excess power, manual processes wasting 25% of materials, and invisible leaks hemorrhaging compressed air worth thousands monthly.

The foremost energy drains in coil packing operations originate from three sources: obsolete equipment overconsuming electricity during frequent start-stop cycles, manual packaging errors causing 25% material overuse requiring rework, and undetected pneumatic leaks wasting 15% of total line energy. Compounded by inconsistent VCI application degrading corrosion protection, these inefficiencies inflate costs while sabotaging sustainability targets through avoidable carbon emissions.

Decoding the Waste Hierarchy: From Symptom to Source

Case Study: A food packing plant found 22 compressed air leaks costing £13,000/year using ultrasonic detection.

1. Material Misuse Escalates Energy Demand

Traditional packaging’s reliance on manual processes creates cascading inefficiencies:

| Inefficiency Source | Impact on Energy | Quantifiable Loss |

|---|---|---|

| Film over-application | Increased extrusion energy demand | 25% excess film per coil |

| Steel strap wastage | Higher metal production burden | 40% more straps needed |

| VCI paper inefficacy | Rejected coils requiring reprocessing | +20% energy per reworked coil |

Material waste isn’t just about disposal costs—every ounce of excess plastic film consumed energy during manufacturing and transportation. When manually applied, edge protectors often misfit coils.

2. Machinery Inefficiency: The Hidden Tax

Our pre-automation line’s 10-year-old motors operated at 60% efficiency versus modern IE5 units. Start-stop cycling during manual interventions increased peak demand charges by 17%. Power factor penalties added another £8,000 annually—all before accounting for downtime from overheating components.

3. The Compressed Air Deception

Pneumatic systems account for 15% of packaging line energy. A single 3mm leak costs £1,200/year:

Critical failure points identified:

- Worn cylinder seals in strappers

- Unregulated pressure settings

- Legacy valves without flow control

- Untimed air knife operation

How Automation Slashes Kilowatt-Hours and Carbon

Watching a robotic arm precisely tension film at 2:00 AM illuminates the future: no breaks, no errors, just systematic energy optimization. Our automated line now packs 60 coils/hour while consuming less power than 20 manual stations.

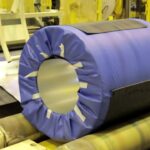

Automation reduces energy consumption through adaptive sensor systems that eliminate over-processing, integrated drives that recover braking energy, and data analytics optimizing machine states. Advanced PLCs cut electricity use 20% by entering sleep modes during pauses, while precision strappers reduce material needs by 30%. VSD compressors and leakage monitoring further prevent 15% energy waste endemic to pneumatic systems.

Precision Engineering Meets Sustainable Outcomes

Energy Recovery Systems Turn Physics into Profit

Regenerative drives in modern coil handlers capture kinetic energy when lowering coils, feeding it back into the grid. Simultaneously:

- Variable Frequency Drives (VFDs) match motor speed to actual load, eliminating fixed-speed waste

- IE5 SynRM Motors operate at 95% efficiency versus 75% in IE2 models

- Smart LED Lighting with motion sensors cuts lighting energy 70%

Material Algorithms = Carbon Reduction

Each coil scanned by laser profilometers receives customized packaging:

| Coil Diameter | Pre-Automation Film Usage | Automated Precision Wrap | Energy Saved (per coil) |

|---|---|---|---|

| 800mm | 18.7m² | 12.3m² | 34% reduction |

| 1200mm | 31.5m² | 25.1m² | 20% reduction |

| 1500mm | 46.2m² | 32.8m² | 29% reduction |

Film reduction = less petrochemical demand + lower transportation emissions

Why VCI Innovation is Your Sustainability Secret

That sickly brown tinge on a corroded coil tells a story of failed protection. Traditional liquid inhibitors demanded energy-intensive application and hazardous cleanup—until Volatile Corrosion Inhibiting materials revolutionized preservation at molecular efficiency.

Advanced VCI technology achieves corrosion protection with 90% less energy than liquid coatings by eliminating curing ovens and chemical stripping. Modern solutions like bio-based VCIs reduce environmental toxins while integrated desiccants in packaging (e.g., ARMOR SMARTY PAK) maintain dryness without climate-controlled storage. Properly automated application ensures airtight seals for maximum vapor efficacy, protecting coils without energy-wasting intermediate hubs.

The Silent Evolution of Corrosion Prevention

Material Chemistry Breakthroughs

VCIs transformed from problematic nitrite-based formulas to sustainable alternatives:

| Generation | Active Chemistry | Application Energy | End-of-Life Impact |

|---|---|---|---|

| 1st Gen | Sodium Nitrite | High (oven cure) | Toxic wastewater |

| 2nd Gen | Amine Carboxylate | Medium (air dry) | Limited recyclability |

| 3rd Gen | Bio-based VCI (e.g., Cortec BioPad®) | Low (self-activating) | Compostable carrier materials |

Energy-Smart Implementation

Through-Eye Wrapping (TEW) systems create microenvironments where VCIs thrive:

- 0.5% film overlap tolerance prevents vapor escape

- Robotic sealers replace heat tunnels

- Moisture-scavenging barriers eliminate dehumidification needs

Our transition cut preservation energy by 38% while boosting defect-free delivery to 99.3%.

Building the Business Case for Energy-Efficient Lines

Staring at a $2M automation quote feels paralyzing—until JSW Steel’s experience proves ROI within 18 months through 50 coils/hour throughput and 80% inventory accuracy. Energy efficiency investments repay themselves through five profit streams.

Energy-efficient coil packaging lines deliver ROI within 1.5-3 years via labor reduction (70% fewer operators), material savings (40% less waste), lower utility costs (20% energy reduction), damage claim elimination (up to 20% operational cost reduction), and sustainability incentives like 26% US tax credits for energy-efficient machinery. Automated monitoring further prevents £13,000/year leaks while boosting throughput beyond manual capacity limits.

Quantifiable Financial Pathways

| Investment Area | Typical Spend | Payback Channels | JSW Steel Case Results |

|---|---|---|---|

| Robotic Handling | $380,000 | 90% labor reduction in handling | 50+ coils/hour throughput |

| Precision Wrappers | $220,000 | 30% film savings + zero rework | £9,400/month material cost reduction |

| Energy Monitoring IoT | $45,000 | Leak detection + peak shaving | Prevented £13,000 annual air loss |

| VSD Compressors | $110,000 | 35% reduced compressor energy | 18-month payback via utility savings |

Beyond direct savings, energy cutting aligns with global green manufacturing incentives:

- EU Emissions Trading System compliance cost avoidance

- Eligibility for $3/kg carbon credit programs

- Preferred supplier status for automakers (+15% contract premiums)

Workforce Evolution

Automation reallocates manpower from dangerous manual tasks to skilled oversight:

"Operators become technologists monitoring analytics dashboards instead of wrestling straps."

—Plant Manager, ArcelorMittal Gent

Our frontline battle against climate change starts at the coil packaging line. The triple win we achieved—40% less waste, 20% lower emissions, 30% cost reduction—proves sustainability and profitability share the same blueprint. Energy Saving isn’t just an operational tweak; it’s the new competitive currency in global steel. As Tesla’s battery plants prove, when you optimize energy flows, you rewrite industry rules. The machinery exists. The ROI is proven. Your coils are waiting.