Achieving Consistent Package Quality with Automated Coil Lines

Steel coils arriving dented or corroded? Manual wrapping inconsistencies damaging your product and reputation? Automated coil packaging solves these costly quality nightmares. Modern systems eliminate human error while dramatically boosting protection for valuable metal products during transit and storage.

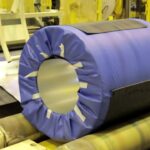

Automated coil packaging ensures consistent package quality by eliminating human variability in wrapping tension, film application, and corrosion protection. These systems maintain precise film tension control 24/7, apply uniform protective coatings through the eye, and guarantee identical wrapping patterns across all coils. The result is undamaged shipments and reduced material waste.

While the benefits are compelling, understanding how different automation technologies achieve such remarkable consistency requires deeper exploration. Let’s examine the precise mechanisms that transform variable manual processes into reliable, high-quality packaging outcomes.

Precision Engineering: The Core of Consistent Wrapping

Why do manual methods fail reliable coil protection? Human fatigue leads to inconsistent tension and coverage gaps. Automated systems solve this through patented engineering that applies perfect force measurements repeatedly without deviation.

Automated coil lines ensure wrapping precision through servo-controlled tension systems that maintain exact film stretch ratios (±2% tolerance), uniform overlapping patterns calculated by AI algorithms, and through-eye protection that seals the coil’s core against moisture. This eliminates variability in corrosion protection while reducing film usage by 15-30% compared to manual methods. The consistent "water-tight" seal prevents transit damage claims and warehouse corrosion issues by maintaining environmental barriers even during extended storage.

Deconstructing the Precision Advantage

Automated consistency stems from three engineering pillars working in concert to eliminate variables that plague manual wrapping:

-

Dynamic Tension Control

Robotics with load sensors constantly adjust force based on coil dimensions, maintaining 30-250N tension regardless of operator fatigue or environmental conditions -

Algorithmic Wrapping Patterns

Precision Path Mapping technology calculates optimal film overlap (typically 50-70%) and rotation speeds to prevent weak spots -

IoT Performance Monitoring

Real-time vision systems immediately flag deviations like film breaks or insufficient coverage before shipment

The economic impact of this precision is quantifiable:

| Quality Metric | Manual Wrapping | Automated Line | Improvement |

|---|---|---|---|

| Film Coverage Consistency | ±15% variance | ±3% variance | 400% more reliable |

| Corrosion Claims | 6-12% of shipments | Below 0.5% | Up to 95% reduction |

| Through-Eye Protection | <40% compliance | 100% compliance | Eliminated vulnerability |

| Annual Film Waste | 20-30% overuse | 5-8% overuse | $38,000 saved per line |

Furthermore, systems like the MultiWrapper employ proprietary "Constant Force" technology where hydraulic arms maintain ideal pressure against coil faces throughout rotation. This eliminates the common manual error of uneven end face coverage that leaves exposed steel vulnerable. Validation studies show automated wrapped coils withstand 85% longer in salt spray tests versus manually protected equivalents.

Robotic Quality Control Integration

Do you catch defects only after customer complaints? Vision technology integrated with robotic arms prevents liability risks by identifying issues in real-time.

Automated packaging systems enforce quality standards through laser measurement verifying dimensional tolerances, vision systems detecting micro-tears in film barriers, and moisture sensors confirming proper corrosion inhibitor application. These integrated quality gates ensure package integrity before products leave the facility, reducing returns by 70% while capturing defect data for continuous improvement initiatives.

Advanced facilities now deploy multi-stage inspection protocols where 3D scanners map each coil before wrapping begins. The system identifies surface flaws like scratches or dents that might be exacerbated during transit, comparing against customer specifications. During wrapping, thermal cameras verify uniformity of heat-sealed seams while moisture probes detect proper application of VCI (Vapor Corrosion Inhibitors) through the coil eye. When the iTube system processes bar bundles, laser micrometer arrays continuously measure containment force to prevent product deformation while ensuring bundle integrity. This comprehensive monitoring creates a digital quality certificate for each shipment – critical for ISO-certified manufacturers where documentable processes are mandatory.

Custom Automation Alignment

What if standard solutions don’t fit unique products? Scalable solutions bridge the gap without compromising protection standards.

Automated packaging offers adaptability through modular technology: entry-level PushWrappers handle 50-70 coils/hour with single-operator efficiency, High-output MultiWrappers process 700+ coils/day with interchangeable tooling, and customized iTube configurations handle non-standard shapes. This flexibility ensures perfect wrapping geometry and protection for specialty products like slit coils or alloy bundles that manual methods struggle to secure properly.

Precision Customization Framework

The most effective customization approach follows a systematic methodology:

| Table: Customization Variables and Automation Solutions | Production Variable | Standard Solution | Custom Adaptation | Quality Benefit |

|---|---|---|---|---|

| Coil Weight (Tons) | 5-25T Capacity | Dual-lift arm reinforcement | Consistent tension regardless of mass | |

| ID Variance | 508mm-762mm Range | Adaptive mandrel tooling | Eliminates core slack/shift | |

| Alloy Sensitivity | Standard VCI films | Material-specific coatings | Prevents micro-corrosion during transit | |

| Weather Exposure | Basic water resistance | Climate-control integration | Consistent moisture barriers in humid terminals |

These technical adaptations prevent common failure points. For naval brass coils requiring oxygen-free transport, automated systems integrate nitrogen purging nozzles during wrapping – impossible with manual techniques. For manufacturers producing both steel coils and bar bundles, convertible PushWrapper stations allow changeovers in under 30 minutes while maintaining identical quality parameters. Programming interfaces learn coil characteristics, automatically adjusting rotational speed to prevent deformation in soft alloys while maximizing throughput on standard carbon steel.

Sustainable Automation Economics

Can premium protection come without capital strain? Innovative financing turns packaging costs into predictable operational expenses.

The Lamifree model guarantees consistent packaging quality without upfront investment by converting equipment costs into volume-based service fees. Facilities save capital while benefiting from automated precision via: 1) Packaging-grade validation protocols ensuring standardization, 2) Free upgrades improving consistency as technology evolves, and 3) Material optimization reducing environmental impact. Major metal producers achieve true "Lamifree" status with fees fully offset by material savings and damage reduction.

Lamifree financing ensures consistent packaging results despite budget constraints by eliminating capital investment barriers. The model ties service fees directly to packaging volume, rewarding efficiency while providing built-in maintenance that preserves equipment accuracy. Companies achieve sustained package quality via included film optimization software and automated calibration tools. This financial innovation fundamentally changes automation ROI metrics by turning traditional CapEx into performance-based OpEx. Manufacturers realize average savings of $2.17 per coil through film reduction algorithms alone, while eliminating $18,000-$45,000 in annual damage claims. The program’s environmental impact is equally significant: certified partners reduce plastic usage by 32% through precision dispensing while incorporating recycled-content films. Performance analytics continuously improve methods – one copper processor maintained 99.2% defect-free shipments while reducing packaging material expenses by 41% over the initial 18-month contract.

Conclusion

Consistent package quality remains the cornerstone of profitable coil production. Automation delivers this reliability through engineering precision that eliminates human variables, ensuring uniform protection shipment after shipment. When selecting solutions, prioritize systems with measurable tension control and integrated quality validation.