Description

Understanding the Welding Line

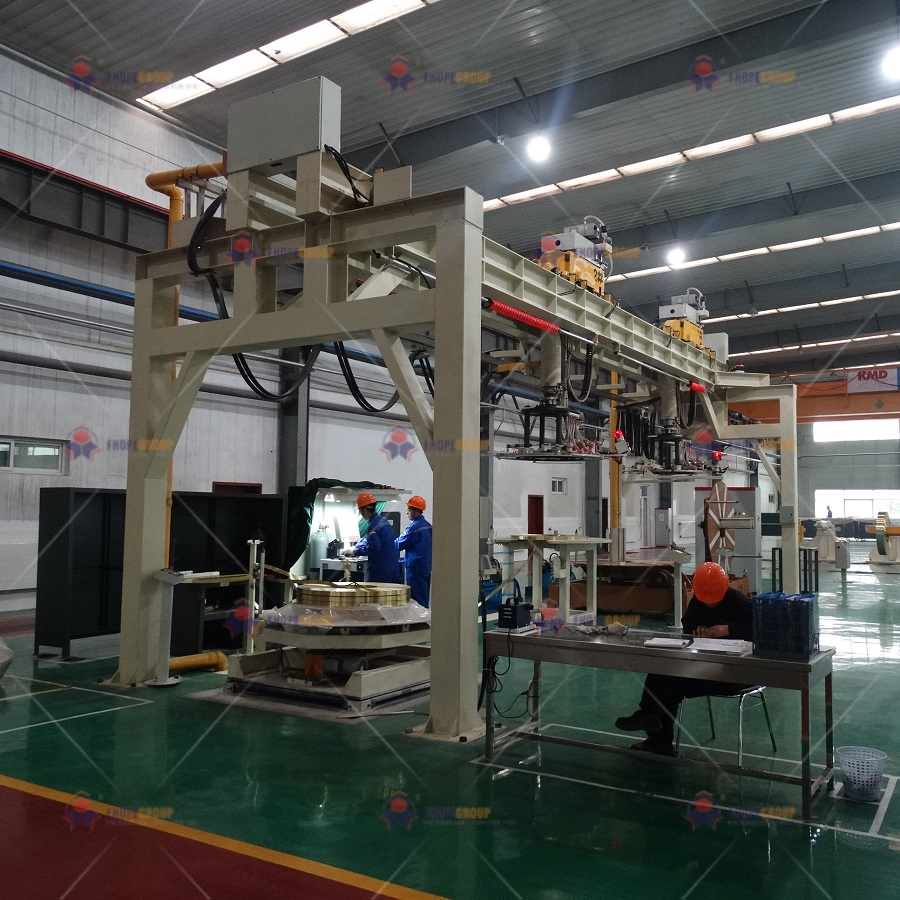

The welding line is a crucial element that combines a framework and individual equipment units to facilitate an efficient and high-quality welding process. By automating and streamlining the handling and welding of brass copper strips, this equipment ensures consistent results and optimizes productivity.

The Framework and Individual Equipment Units

The welding line’s framework serves as the foundation of the entire system, providing structural support and stability to the various equipment units. These units, aligned on the same axis, enable the smooth transfer of copper coils between each stage of the welding process.

Efficient Equipment Alignment for Smooth Transfer

The alignment of the individual equipment units is a critical factor in the welding line’s efficiency. By maintaining synchronized axes, these units enable seamless transfer of copper coils, minimizing downtime and maximizing productivity. This alignment ensures a smooth flow of coils through each stage of the welding process, reducing bottlenecks and optimizing workflow.

Versatility and Flexibility with Alternating Upenders

One notable feature of the welding line is the use of alternating upenders, which can be interchanged to provide increased versatility and flexibility in the welding process. This feature is particularly beneficial when handling different types of copper coils or accommodating changes in production volume. The ability to adapt quickly and efficiently enhances overall operational efficiency.

Precise Positioning with Vacuum Chuck Integration

Precise positioning is crucial for achieving high-quality welds in brass copper strip manufacturing. The welding line incorporates a vacuum chuck system that seamlessly works throughout the entire process. This integration ensures secure and stable placement of the copper coils, eliminating any movement or misalignment that could compromise welding quality. The result is consistent and accurate positioning, leading to flawless welds.

Enhancing Quality and Consistency with Rotate-Lifter Function

To further enhance the quality and consistency of the welds, the welding line incorporates a rotate-lifter function. This function ensures correct positioning of the copper coils for welding, optimizing the welding parameters and improving the overall strength and durability of the joints. The rotate-lifter function adds an extra layer of precision to the welding process, resulting in high-quality and reliable welds.

Convenient Operating Design for Maintenance and Repair

Maintenance and repair are inevitable aspects of any industrial equipment. The design of the welding line takes convenience into consideration. The transit platform features strategically placed gaps that provide easy access to the lower part of the equipment. This design simplifies maintenance and repair tasks, reducing downtime and ensuring seamless operation.

Benefits of Using a Welding Line

Using a brass copper strip welding line offers numerous benefits to manufacturers, including:

Enhanced efficiency and productivity through automation and streamlined processes.

Consistent and high-quality welds, improving the overall strength and durability of the joints.

Reduction in manual labor, minimizing the risk of errors and increasing operational efficiency.

Versatility and flexibility to handle different types of copper coils and accommodate changing production demands.

Cost savings through optimized resource utilization and reduced material wastage.

FAQs

Q: What are the main advantages of using a brass copper strip welding line?

A: A brass copper strip welding line offers enhanced efficiency, consistent quality, reduced manual labor, versatility, and cost savings.

Q: Can a welding line accommodate different sizes of copper coils?

A: Yes, welding lines can be adjusted to handle various sizes of copper coils, making them suitable for different production requirements.

Q: Are welding lines only used in specific industries?

A: No, welding lines find applications in various industries, including electrical, automotive, HVAC, appliances, and renewable energy sectors.

Reviews

There are no reviews yet.