-

Key Features to Look for in a Modern Coil Packing Line

Watching coils get damaged during packaging is painful. Dented edges, corrosion from inadequate wrapping, and production bottlenecks cost thousands per…

-

Key Features to Look for in a Modern Coil Packing Line

Watching coils get damaged during packaging is painful. Dented edges, corrosion from inadequate wrapping, and production bottlenecks cost thousands per…

Follow Us

-

Key Features to Look for in a Modern Coil Packing Line

Watching coils get damaged during packaging is painful. Dented edges, corrosion from inadequate wrapping, and production bottlenecks cost thousands per…

-

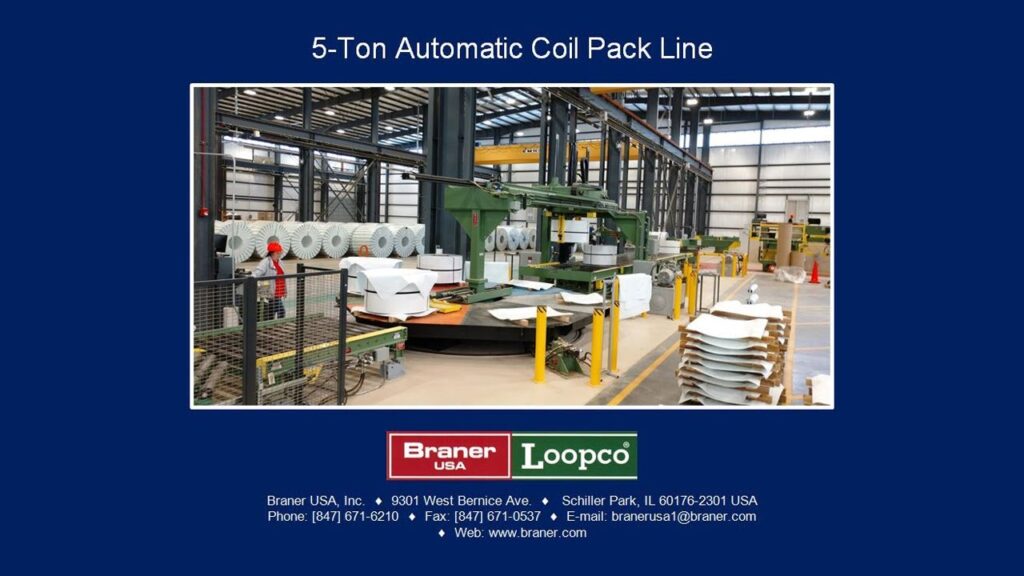

Custom Coil Packing Line Solutions for the Metals Industry

Metal producers face constant pressure: coils damaged during transit, inconsistent packaging slowing throughput, and rigid systems failing to handle diverse…

-

Automated Coil Packing Lines: Boosting Productivity and Reducing Costs

Manual coil packaging is costing your metal production line dearly. Every minute spent strapping, wrapping, and labeling coils by hand…

-

Exploring Different Types of Coil Packing Lines: Which is Right for You?

Struggling to choose the optimal coil packaging solution for your metal production facility? Inadequate packaging leads to damaged goods, customer…

-

Maximizing Throughput: Efficiency Secrets for Coil Packing Lines

Struggling with bottlenecks in your coil packing operations? Slowdowns erode profits and frustrate teams, leaving you vulnerable to competitors. When…