Uncategorized

-

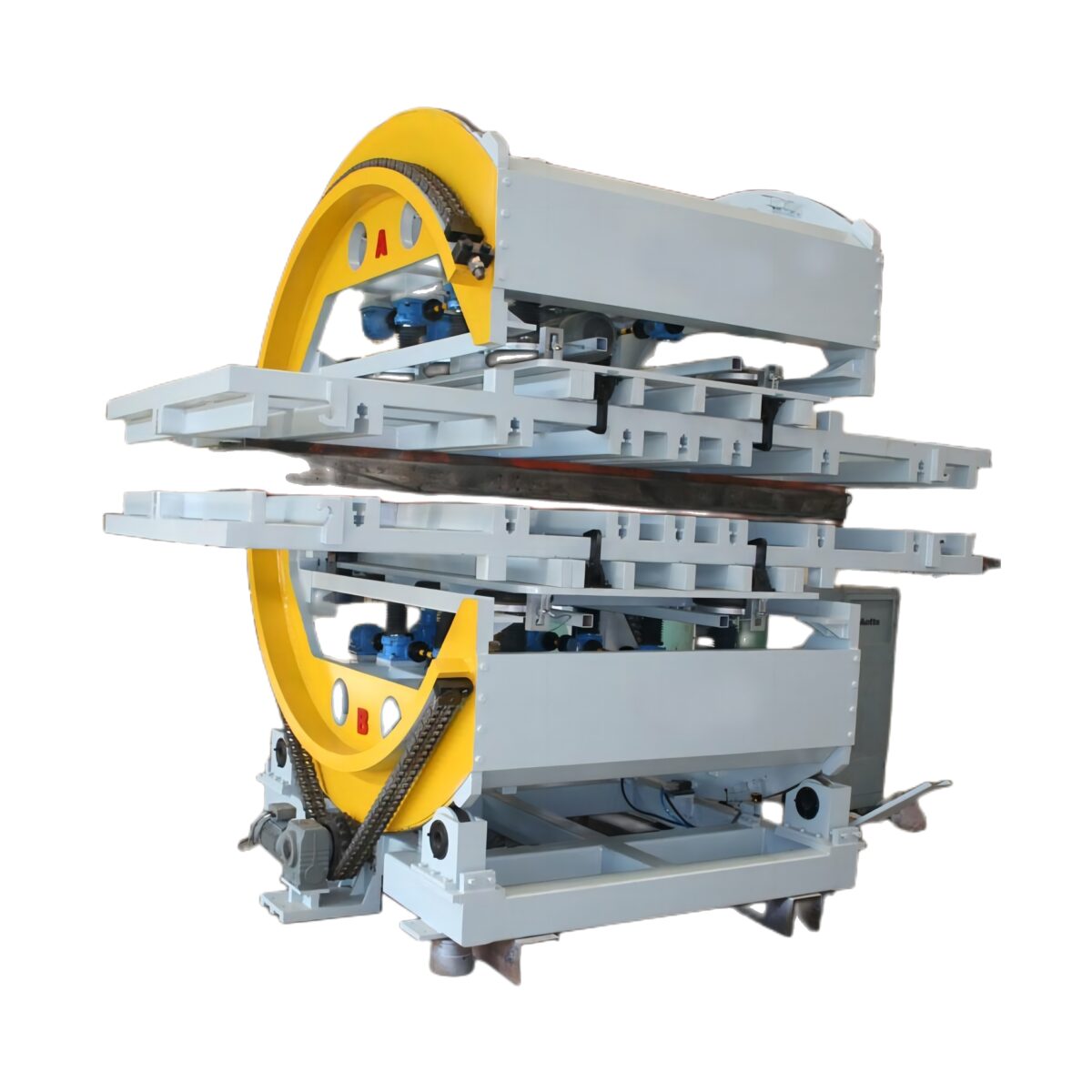

Pallet Machine for Shaping and Transporting Objects

Title: Innovative Upender Pallet Machine for Moulder and Roll Objects Description: ————————————- H2: Introduction ————————————- Welcome to this captivating video…

-

A Divine Soul: Personal Transformation with Bro. P. Upender – E182

Title: “Unveiling the Divine Essence | Bro. P. Upender’s Inspiring Transformation – E182” Description: H2: Introduction Discover the profound spiritual…

-

Biblical Podcast: Brother P. Upender, Episode 99.

Title: “BIBLICALLY SPEAKING… I EPISODE – 99 I CHRISTIAN PODCAST I Bro. P. Upender” Description: Biblically Speaking: A Christian Podcast…

-

Biblical Insights: Episode 108 – Christian Podcast with Bro. P. Upender

Title: “BIBLICALLY SPEAKING… I EPISODE – 108 I CHRISTIAN PODCAST I Bro. P. Upender” Description: H2: Introduction: Welcome to “Biblically…

-

Episode 97: Christian Podcast with Bro. P. Upender Biblically Explained.

Title: “BIBLICALLY SPEAKING… I EPISODE – 97 I CHRISTIAN PODCAST I Bro. P. Upender” Description: H2: Welcome to “Biblically Speaking”…

-

Semi-Automatic Strapping Machine with Model Number GPSAS20.

Title: Strapping Machine – 3 GPSAS20 Semi Automatic Strapping Machine Description: Strapping machines are a vital tool for bundling cartons…

-

Steel coil horizontal packer

FHOPE company specializes in providing horizontal wrapper machines for steel coils. Steel coils are often used in a variety of…

-

Flipper Goods For 180 Degreen

A “C type structure” is a design for heavy object 180 degree sheet turning equipment. This design typically consists of…

-

Strapping for steel coil

-

3 leading Coil packing machine manufacturers

1. FHOPE PACKAGING MACHINERY CO.,LTD We would like to introduce company FHOPE PACKAGING MACHINERY CO.,LTD as leading manufacturer of end of…

Follow Us

Recent Posts

- Key Features to Look for in a Modern Coil Packing Line

- Custom Coil Packing Line Solutions for the Metals Industry

- Automated Coil Packing Lines: Boosting Productivity and Reducing Costs

- Exploring Different Types of Coil Packing Lines: Which is Right for You?

- Maximizing Throughput: Efficiency Secrets for Coil Packing Lines

Categories

- Coil packaging line 108

- Coil packing machine 303

- cooper tube coil packing line 1

- Full-auto cable packing line 1

- Info 35

- orbital stretch wrapper 502

- Pallet wrapping machine 9

- PET STRAPPING MACHINE 6

- PVC Pipe packing line 1

- Shrinking machine 14

- Steel wire coil packing line 80

- Strapping machine 921

- Strapping Machine Solutions 2

- Tube Pipe Packaging Solution 2

- Uncategorized 282

- Upender 498

- 包装线 9

- 托盘缠绕包装机 1

- 收缩机 3

- 水平缠绕包装机 2

Tags

coil packaging line coil packaging machine Coil packing line coil packing machine coil protector coil wrapping machine horizontal stretch wrapper infromation orbital stretch wrapper orbital wrapping machine packaging packaging line packaging machine packing machine pallet dispenser palletizer pallet stacker pallet wrapping machine pallitizing shrinking machine strapping strapping machine stretch hood machine stretch wrapper stretch wrapping machine strtech wrapper tilter tube packing machine tying machine wire coil compactor