strapping machine

-

Strapping System For Paper-Pile

Stacked paper vertical strapping Stacked paper vertical strapping refers to a method of bundling together stacks of paper using a…

-

Strapping Machine for bricks & blocks

Different Strapping Machines for bricks & blocks applications. There are mainly 2 different strappin methods for bricks and clocks stacking…

-

Economy automatic strapping machine with PP

An economy automatic strapping machine for PP strapping. Easy operation and simple maintenance. It is suitable for strapping on automatic…

-

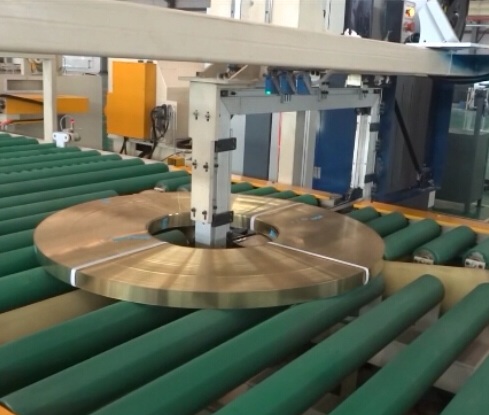

Automatic strapping machine for copper coil

This is a kind of strapping machine specially designed for various metal coil such as copper coil, steel coil, aluminium…

-

the rotary arm stretch wrapping machine for pallet

Electro-Place Rotary Tower pallet wrapper, is really a sturdy wrapper created, supported and manufactured to provide difficulty free of charge…

-

It is an automatic strapping machine, . This device includes a solid style, and a system control built-in with conveyor lines….

-

Strapping machine and pallet wrapping machine

Strapping machine: The strapping machine, made by Chinese company, is an auto strap loop ejection that comes with…

-

Strapping machine construction and easy operations

Corp. is currently providing the new evolutionary, ROM-Fusion, high-good quality, competitively priced, entry-level automatic strapping machine. Well suited for strapping…

-

conveyorized strapping system with rotary arm stretch wrapper

ISO 9001: 2008 qualified manufacturer of strapping. Varieties such as polyester, polypropylene and steel strapping. Different functions consist of rust,…

-

Pallet strapping machines ensure consistent strap load

Pallet strapping machines ensure consistent strap load and placement integrity for top manufacturing programs. Obtainable in semi- and fully-automatic versions,…

Follow Us

Recent Posts

- Key Features to Look for in a Modern Coil Packing Line

- Custom Coil Packing Line Solutions for the Metals Industry

- Automated Coil Packing Lines: Boosting Productivity and Reducing Costs

- Exploring Different Types of Coil Packing Lines: Which is Right for You?

- Maximizing Throughput: Efficiency Secrets for Coil Packing Lines

Categories

- Coil packaging line 108

- Coil packing machine 303

- cooper tube coil packing line 1

- Full-auto cable packing line 1

- Info 35

- orbital stretch wrapper 502

- Pallet wrapping machine 9

- PET STRAPPING MACHINE 6

- PVC Pipe packing line 1

- Shrinking machine 14

- Steel wire coil packing line 80

- Strapping machine 921

- Strapping Machine Solutions 2

- Tube Pipe Packaging Solution 2

- Uncategorized 282

- Upender 498

- 包装线 9

- 托盘缠绕包装机 1

- 收缩机 3

- 水平缠绕包装机 2

Tags

coil packaging line coil packaging machine Coil packing line coil packing machine coil protector coil wrapping machine horizontal stretch wrapper infromation orbital stretch wrapper orbital wrapping machine packaging packaging line packaging machine packing machine pallet dispenser palletizer pallet stacker pallet wrapping machine pallitizing shrinking machine strapping strapping machine stretch hood machine stretch wrapper stretch wrapping machine strtech wrapper tilter tube packing machine tying machine wire coil compactor