strapping

-

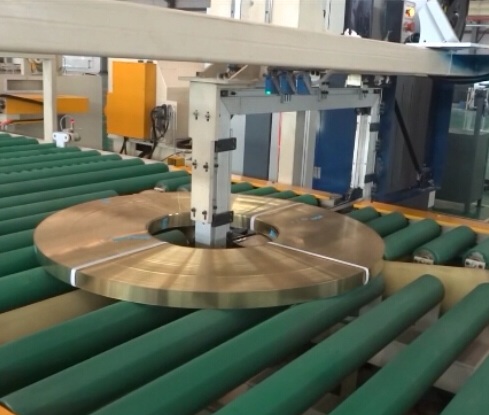

Automatic strapping machine for copper coil

This is a kind of strapping machine specially designed for various metal coil such as copper coil, steel coil, aluminium…

-

Situation Reloading by wrapping machine

The latest advancements in the event/box managing gear has noticed an upswing of automatic machines that can completely speed up…

-

Circumstance Loading by machine

Case Developing Situation formers can provide a perfect starting point to stretch packaging automation. The machines are designed to reduce…

-

Circumstance Closing and Case Securing

Case Case and Closing Sealing Automated circumstance sealers are accessible for repaired or unique measured situations and most have effortless…

-

automatic Packaging

Box and Case Managing Back in the time, every little thing was provided in brown containers or instances which is…

-

Stretch is actually a semi-automatic pallet wrapper

Stretch is a semi-automatic pallet wrapper with fully automated characteristics. It can be controlled by a wi-fi distant. This high-performance…

-

Overall Options packing machinery

The Shrink wrappers are Great britain designed and built for 24/7 operation in small places. The entry level machines can…

-

Total Solutions packing info

Euroflow Engineering design and produce stainless processing and handling equipment for the foods and associated industries. Company Account Situated inBoston…

-

semi-automated stretch wrappers

Flex Collection provides High Profile Standard and Low Account Standard models Long lasting building, consumer-pleasant characteristics deliver high benefit overall…

-

The brand new accessory for the manufacturing

Engineering, operated by Expert Mach, announced these days that it is growing its Center of Engineering and Manufacturing Superiority in…

Follow Us

Recent Posts

- Key Features to Look for in a Modern Coil Packing Line

- Custom Coil Packing Line Solutions for the Metals Industry

- Automated Coil Packing Lines: Boosting Productivity and Reducing Costs

- Exploring Different Types of Coil Packing Lines: Which is Right for You?

- Maximizing Throughput: Efficiency Secrets for Coil Packing Lines

Categories

- Coil packaging line 108

- Coil packing machine 303

- cooper tube coil packing line 1

- Full-auto cable packing line 1

- Info 35

- orbital stretch wrapper 502

- Pallet wrapping machine 9

- PET STRAPPING MACHINE 6

- PVC Pipe packing line 1

- Shrinking machine 14

- Steel wire coil packing line 80

- Strapping machine 921

- Strapping Machine Solutions 2

- Tube Pipe Packaging Solution 2

- Uncategorized 282

- Upender 498

- 包装线 9

- 托盘缠绕包装机 1

- 收缩机 3

- 水平缠绕包装机 2

Tags

coil packaging line coil packaging machine Coil packing line coil packing machine coil protector coil wrapping machine horizontal stretch wrapper infromation orbital stretch wrapper orbital wrapping machine packaging packaging line packaging machine packing machine pallet dispenser palletizer pallet stacker pallet wrapping machine pallitizing shrinking machine strapping strapping machine stretch hood machine stretch wrapper stretch wrapping machine strtech wrapper tilter tube packing machine tying machine wire coil compactor