Problem: Are you struggling with coil packaging bottlenecks – material waste, labor inefficiencies, and unpredictable downtime eating into your bottom line? Agitate: These aren’t just operational headaches; they translate to millions in lost productivity, damaged goods, and missed customer commitments that directly impact your P&L. Solution: A strategically optimized coil packing line investment, guided by rigorous procurement methodology, transforms these pain points into measurable competitive advantages.

To optimize coil packing line investments, procurement managers must implement a three-pillar approach: 1) Strategic vendor selection focusing on lifecycle costs over initial price, 2) Comprehensive cost-benefit analysis quantifying both tangible and intangible factors, and 3) Continuous efficiency monitoring through IoT-enabled systems. This methodology typically reduces operational costs by 18-25%, increases throughput by 30%, and cuts material waste by up to 15% within 12-18 months, delivering ROI that exceeds traditional CAPEX evaluation metrics.

The journey from pain points to profitability requires moving beyond reactive purchasing. What follows is your evidence-based roadmap for transforming coil packaging from a cost center to a value driver – covering vendor negotiation tactics, hidden cost identification frameworks, and real-time efficiency tracking systems that collectively redefine procurement excellence in industrial packaging.

Strategic Procurement Frameworks for Coil Packaging

Selecting coil packaging equipment solely on sticker price guarantees long-term inefficiency. Modern procurement demands evaluating systems through the lens of Total Cost of Ownership (TCO) and operational synergy. When legacy machines cause production halts or require constant manual intervention, the true expense emerges in delayed shipments and overtime labor – costs rarely captured in initial quotes.

Strategic procurement for coil lines requires evaluating vendors on lifecycle support capabilities, technology scalability, and integration compatibility with existing plant systems. Prioritize partners offering modular designs that allow incremental upgrades – this future-proofs investments against evolving production volumes and material specifications while avoiding costly full-line replacements every 5-7 years.

Beyond Price Tags: The Lifecycle Value Assessment

Procurement excellence begins with redefining value metrics. Traditional RFPs overemphasize machine specifications while underweighting critical factors like:

- Maintenance ecosystem accessibility: Suppliers with local technical teams reduce mean-time-to-repair (MTTR) by 40-60% compared to offshore providers

- Energy consumption profiles: Modern servo-driven systems consume 30% less power than hydraulic alternatives – saving $18,000+ annually per line

- Training and documentation quality: Comprehensive operator training programs prevent 80% of common operational errors

Leading manufacturers now implement Vendor Qualification Scorecards weighting criteria as follows:

| Evaluation Dimension | Weight (%) | Critical Indicators | Data Source |

|---|---|---|---|

| Technical Capability | 30% | Material compatibility, changeover speed (<5 min), precision tolerance (±0.3mm) | Factory Acceptance Tests |

| Lifecycle Support | 25% | Remote diagnostics coverage, spare parts inventory levels, technician response SLA | Service Level Agreements |

| Financial Stability | 20% | 5-year financial health ratings, R&D investment ratio (>4% revenue) | Audited Financials |

| Operational Synergy | 15% | MES/ERP integration capability, operator skill compatibility | System Demos |

| Sustainability Impact | 10% | Energy Star certification, recyclable packaging material options | ISO 14001 Compliance |

Table: Vendor selection framework weighting both quantitative and qualitative factors

Negotiation Levers for Maximum Value Capture

Armed with TCO data, procurement professionals secure superior terms through:

- Performance-based contracting: Tie 15-20% of payment to measurable KPIs (e.g., <2% downtime in first year)

- Modularization clauses: Ensure future upgrades use standardized interfaces to avoid proprietary lock-in

- Data access requirements: Mandate open-protocol machine data for integration with plant analytics platforms

A tier-1 automotive supplier reduced packaging CAPEX 22% by negotiating bundled maintenance contracts covering 5 years of predictive servicing – transforming fixed costs into variable, performance-linked expenses.

Quantifying Investments Through Cost-Benefit Analysis

Traditional ROI calculations fail to capture the full impact of coil packaging automation. When a major aluminum producer evaluated a $1.2M automated line, standard finance models showed 4.2-year payback – missing $380,000 in annual hidden benefits from reduced material damage claims and inventory carrying costs.

Effective cost-benefit analysis must model both direct financial metrics (CAPEX, labor savings) and indirect value drivers like quality consistency, inventory reduction, and sustainability compliance. Advanced models incorporate risk-adjusted scenarios showing how automation mitigates $45,000+ per incident in coil damage during transit – a frequent hidden cost in manual operations.

Building Multi-Dimensional Financial Models

Transform spreadsheet exercises into strategic decision tools by:

Step 1: Capture Comprehensive Cost Variables

- Direct costs: Equipment, installation, commissioning

- Indirect costs: Facility modifications, utility upgrades

- Operational costs: Consumables (strapping, film), energy, maintenance labor

- Risk costs: Damage rates, warranty claims, compliance penalties

Step 2: Quantify Tangible & Intangible Benefits

- Labor reduction: Automated lines typically require 60-70% fewer operators

- Material savings: Precision tension control reduces strap/film waste by 12-18%

- Quality gains: Automated systems achieve <0.5% damage rate vs. 2-4% manual

- Space optimization: Vertical coil handling reclaims 30% floor space

Step 3: Run Scenario Analysis

Model outcomes across three scenarios:

- Conservative: 15% labor reduction, 8% material savings

- Expected: 25% labor reduction, 12% material savings

- Optimistic: 40% labor reduction, 18% material savings with AI optimization

A steel service center used this approach to justify $2.4M in automation – the model revealed $310,000/year in unaccounted savings from reduced workers’ compensation claims due to eliminating manual coil handling.

Measuring and Maximizing Operational Efficiency

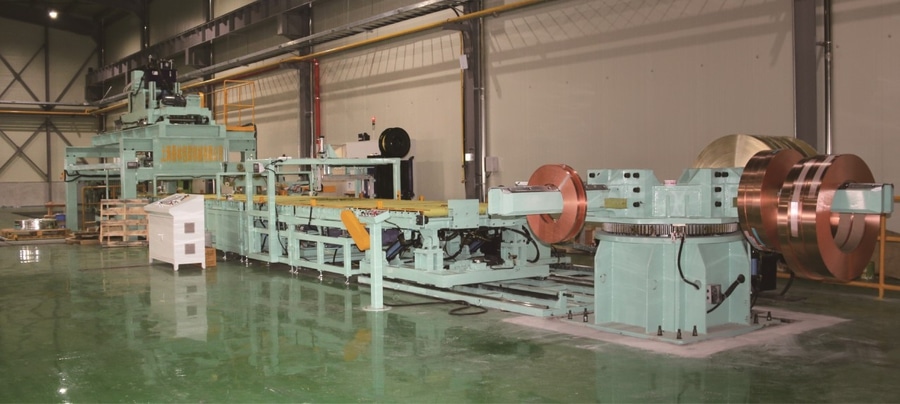

Efficiency gains in coil packaging extend beyond speed metrics. When a copper manufacturer focused solely on line speed (coils/hour), they overlooked changeover downtime consuming 18% of productive capacity – until IoT sensors revealed the true bottleneck.

Operational efficiency requires monitoring three interconnected layers: equipment effectiveness (OEE), material utilization rates, and labor productivity. Leading installations deploy IIoT-enabled systems providing real-time visibility into changeover duration, energy consumption per coil, and tension consistency – enabling data-driven adjustments that boost overall efficiency by 25-40% within six months.

The Efficiency Optimization Framework

Implement continuous improvement through:

Real-Time Performance Monitoring

- Sensor networks tracking: Vibration patterns, motor currents, thermal signatures

- OEE calculation: (Availability × Performance × Quality)

- Example: Detecting 0.3mm belt misalignment before it causes $20,000 in scrapped coils

Predictive Maintenance Integration

- Machine learning algorithms analyzing historical failure patterns

- Maintenance cost reduction: 25-35% vs. scheduled servicing

- Case: Vibration analysis predicting bearing failure 14 days in advance

Automation Tier Optimization Matrix

Match technology to operational needs:

| Automation Level | Throughput | Changeover Time | Labor Requirement | Best Application |

|---|---|---|---|---|

| Manual | <5 coils/hr | 5-10 min | 3-4 operators | Low-volume specialty alloys |

| Semi-Auto | 10-15 coils/hr | 8-12 min | 2 operators | Medium-volume mixed SKUs |

| Robotic | 20-30 coils/hr | 3-5 min | 0.5 FTE | High-volume standard coils |

| AI-Optimized | 35-50+ coils/hr | <90 sec | Remote monitoring | 24/7 operations with <1% downtime |

Table: Matching automation levels to production profiles

Future-Proofing Packaging Investments

Future-proof coil packaging investments requires selecting modular, data-capable systems with open-architecture controls that allow incremental technology upgrades. Prioritize vendors offering IoT-ready machinery with API access – enabling seamless integration of AI optimization modules, AR maintenance guides, and sustainability tracking without costly retrofits, typically extending equipment lifespan by 40% while reducing technology obsolescence risk.

The Scalability Imperative

Avoid technological dead-ends through:

Modular Design Principles

- Component-based architecture allowing piecemeal upgrades

- Example: Start with automated strapping, add robotic palletizing later

- Capital preservation: Scale capabilities as production volumes increase

Data Infrastructure Foundation

- OPC-UA or MQTT protocol compatibility

- Cloud-based analytics platform integration

- Data utilization: Machine learning algorithms optimizing settings per coil alloy

Sustainability Compliance Pathways

- Carbon tracking modules quantifying emissions per packaged coil

- Material reduction algorithms minimizing film/strap usage

- Regulatory readiness: Automated documentation for ESG reporting

Leading manufacturers now deploy "digital twin" simulations before physical installation – virtually testing packaging configurations across different coil dimensions and materials. This eliminates 80% of commissioning issues while creating a continuous optimization feedback loop. When combined with performance-based service contracts covering software updates and predictive maintenance, these approaches deliver 50% lower lifecycle costs versus conventional packaging lines over a 10-year horizon.

Conclusion: The Strategic Procurement Advantage

Optimizing coil packing line investments transcends equipment selection – it’s about building an integrated operational ecosystem where procurement strategy, financial analysis, and efficiency monitoring create compounding value. By implementing vendor selection frameworks focused on lifecycle value, cost-benefit models that capture hidden operational variables, and IIoT-enabled efficiency tracking, procurement leaders transform packaging from a cost center to a profit accelerator. The result? Sustainable competitive advantage through 25-40% lower total cost per packaged coil, 99%+ shipment integrity, and the agility to scale operations seamlessly. This strategic approach positions procurement as a value driver – directly contributing to the organization’s operational excellence and bottom-line results. For deeper implementation strategies, explore our framework for [Procurement Strategy]() integration across industrial operations.

Leave a Reply

You must be logged in to post a comment.