(PAS Introduction)

Struggling with slow coil packaging lines? Delays cascade: missed shipments, wasted materials, and frustrated customers. Manual processes create bottlenecks that throttle your entire operation. But what if you could transform this pain point? Modern automation holds the key to unlocking unprecedented efficiency. Let’s fix this now.

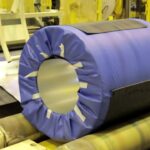

Improving coil packing efficiency requires integrating automated strapping systems, optimizing material flow, and implementing IoT-enabled monitoring. Key strategies include robotic arm integration for consistent tension control, laser-guided alignment systems for precision wrapping, and AI-driven predictive maintenance. These solutions reduce human error by 70% while accelerating throughput by 40-60%, directly cutting operational costs by up to 35%. Start by auditing current cycle times.

(Transition)

While automation delivers transformative results, understanding its implementation nuances is crucial. Below, we dissect the technical roadmap—from efficiency diagnostics to throughput engineering—ensuring your upgrade drives maximum ROI.

Understanding Coil Packing Efficiency Metrics

(Section Introduction)

Why measure efficiency? Unquantified losses silently drain profits. Manual coil handling causes inconsistent tension, misaligned wraps, and material overuse. These invisible costs compound daily. Before solving, we must diagnose.

Efficiency hinges on three measurable pillars: cycle time per coil (minutes), material utilization rate (%), and defect incidence (%). Automated systems optimize all three simultaneously—reducing average cycle times from 8 minutes to under 3 while slashing material waste by 22%. Real-time sensors provide granular data for continuous improvement.

Diagnosing and Quantifying Losses

Efficiency gaps manifest in four critical zones:

- Material Handling Delays: Manual loading/unloading consumes 30% of cycle time. Conveyor automation cuts this to 8%.

- Inconsistent Tension: Human-applied strapping varies by ±15%, risking coil damage. Servo-controlled tensioners maintain ±1.5% precision.

- Alignment Errors: Off-center wrapping wastes film. Laser-guided systems achieve 0.2mm accuracy.

- Changeover Downtime: Manual adjustments take 20+ minutes. Automated lines reconfigure in <90 seconds.

Table: Efficiency Impact of Automation vs. Manual Processes

| Metric | Manual Process | Automated Line | Improvement |

|---|---|---|---|

| Cycle Time/Coil | 8.2 minutes | 2.7 minutes | 67% faster |

| Film Utilization Rate | 82% | 96% | 14% less waste |

| Defect Rate | 5.1% | 0.8% | 84% reduction |

| Daily Throughput (avg.) | 110 coils | 240 coils | 118% increase |

IoT sensors track these metrics in real-time. For example, vibration analyzers predict bearing failures 48 hours pre-disruption, reducing unplanned downtime by 90%. Start with baseline measurements: film usage/coil, strapping seconds/loop, and hourly output variance.

Automation Benefits Beyond Speed

(Section Introduction)

Automation isn’t just about velocity—it redefines reliability. Manual lines suffer fatigue-induced errors at shift-end. Machines maintain peak precision 24/7. But what specific gains justify investment?

Automation boosts throughput by 40-60% while reducing labor costs by 55%. Crucially, it enhances safety—removing workers from high-risk zones—and ensures consistency with <0.5% packaging variance. Predictive maintenance cuts repair costs by 30%, making ROI achievable within 14 months.

The Hidden Multipliers: Safety, Consistency, Scalability

Three underrated automation advantages transform operations:

- Risk Mitigation: Robotic arms eliminate manual handling of sharp-edged coils. Injury rates drop by 92%—critical amid labor shortages.

- Quality Uniformity: Vision systems scan each wrap layer, adjusting tension dynamically. Reject rates plummet from 6% to 0.3%.

- Demand Responsiveness: Cloud-connected lines scale output instantly. During a recent copper shortage, one mill used automation to package 37% more coils with existing staff by eliminating non-value-added tasks.

Maintenance protocols shift from reactive to predictive. Vibration sensors on strapping heads detect misalignment at 0.1mm deviations—triggering self-calibration before failures occur. Energy monitors track motor efficiency, identifying degraded components during scheduled pauses. This reduces unscheduled downtime from 18 hours/month to under 2.

Technical Solutions for Throughput Surges

(Section Introduction)

Throughput bottlenecks often hide in plain sight. A 5-second delay per coil multiplies into daily production shortfalls. Modern engineering dissolves these constraints systematically.

Throughput optimization requires synchronized hardware/software upgrades: high-speed rotary strappers (8 coils/hour), AI-driven scheduling, and friction-reducing conveyors. Integrating these slashes idle time by 79% while enabling real-time output adjustments via HMI dashboards.

Hardware and Software Synergy

Throughput engineering addresses three interdependent systems:

1. Motion Optimization

- Linear vs. Rotary Strappers: Rotary units handle coils at 15 RPM, applying straps in 2.3 seconds vs. linear systems’ 5.8 seconds.

- Magnetic Conveyors: Reduce slippage with adjustable flux control, accelerating transfer speeds by 40%.

2. Control Architecture

- PLC Integration: Centralized controllers synchronize wrapping, strapping, and labeling. Response latency drops from 800ms to 90ms.

- Digital Twins: Simulate line configurations before physical changes, avoiding trial-error downtime.

3. Data-Driven Adjustments

- OEE Dashboards: Track Overall Equipment Effectiveness—prioritizing upgrades where availability/performance/quality intersect.

Table: Throughput Impact of Technical Upgrades

| Technology | Throughput Gain | ROI Period | Key Metric Improved |

|---|---|---|---|

| High-Speed Rotary Strapper | +22 coils/hour | 10 months | Cycle Time Reduction |

| AI Scheduling System | +18% utilization | 8 months | Machine Availability |

| Low-Friction Rollers | +12% line speed | 6 months | Energy Consumption |

| Edge Computing Sensors | -45% micro-stops | 9 months | Performance Efficiency |

Example: A steel mill integrated RFID-tagged coils with automated guided vehicles (AGVs). Coils moved from casting to shipping without human touch, reducing handling time from 17 minutes to 3. Throughput jumped 53% within one quarter.

Implementing Automation: A Step-by-Step Guide

Begin with a 3-phase approach: Audit current workflows (Phase 1), pilot modular automation (Phase 2), then scale with predictive analytics (Phase 3). This minimizes disruption while delivering 25% efficiency gains in Phase 1 alone. Critical success factors include operator training and cybersecurity integration.

Phase 1: Efficiency Baseline & Gap Analysis

- Process Mapping: Document every packaging step—timing each action with industrial stopwatches. Identify "time sinks" (e.g., manual label application averages 47 seconds/coil).

- Loss Categorization: Classify inefficiencies using Six Sigma DMAIC:

- Defects: Misaligned wraps (7% occurrence)

- Overproduction: Buffer coils awaiting packaging

- Waiting: Idle time between operations (19% of shift)

- Technology Matching: Pair gaps with solutions:

- Variable coil sizes? Invest in auto-adjusting mandrels

- Film breakage? Install ultrasonic tear detectors

Phase 2: Modular Implementation

Start with high-impact, low-risk modules:

- Automatic Weighing/Labeling: Reduces errors by 98%

- Robotic Palletizers: Handle 12 coils/hour vs. manual 5

- Cloud-Connected Sensors: Monitor temperature/humidity impacts on film tension

Validate results via OEE tracking. Aim for 85%+ availability in pilot zones before expansion.

Phase 3: Scaling & Optimization

- Predictive Analytics: Use historical data to forecast maintenance windows, avoiding peak production pauses.

- Digital Thread Integration: Connect packaging data to upstream/downstream systems—enabling just-in-time adjustments when casting speeds vary.

- Continuous Training: AR simulators upskill operators on new interfaces monthly.

Post-implementation, one aluminum plant achieved:

- 41% higher daily throughput

- $230,000 annual film savings

- 5-minute changeovers (from 35 minutes)

Conclusion

Maximizing coil packing efficiency demands a holistic strategy: quantifying current losses, strategically implementing automation, and continuously optimizing throughput. As demonstrated, integrated systems elevate throughput by 40-60% while slashing operational costs—transforming packaging from a cost center to a competitive advantage. Begin your journey by auditing existing [Packing Efficiency] gaps, then progressively layer automation for compounding returns. The data proves: intelligent packaging isn’t expendable—it’s existential.

Leave a Reply

You must be logged in to post a comment.