Manufacturing P.P Strapping Rolls: A Comprehensive Guide

P.P strapping rolls, also known as plastic bands or straps, play a crucial role in securing goods and products during transportation and storage. As a proficient technical engineer, I understand the importance of high-quality strapping rolls and the need for a reliable manufacturing plant and machine. In this video, we dive deep into the world of P.P strapping roll manufacturing, exploring the process, key considerations, and providing valuable insights for both manufacturers and users.

The Manufacturing Process

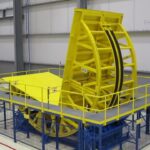

Manufacturing P.P strapping rolls involves several critical steps to ensure the production of high-quality and durable straps. Starting with the selection of the right raw materials, the video explains the importance of using top-grade polypropylene (P.P) and the benefits it offers in terms of strength and flexibility. We then delve into the extrusion process, where the P.P material is melted and shaped into thin and uniform straps. This section offers an in-depth look at the extrusion machinery used and highlights the key factors that influence the quality of the strapping rolls.

Next, we explore the stretching and annealing process, which enhances the tensile strength and resistance of the straps. This step is crucial in ensuring that the P.P strapping rolls can withstand the demands of heavy-duty applications. The video provides valuable insights into the parameters to consider during stretching and annealing, such as temperature, time, and cooling methods.

In the final stages of the manufacturing process, we examine the cutting and winding of the P.P strapping rolls. Precision cutting and proper winding techniques are essential to ensure consistent dimensions and easy handling of the straps. The video highlights the importance of investing in high-quality cutting and winding machines to achieve optimal results.

Quality Control and Testing

Ensuring the quality and reliability of P.P strapping rolls is of utmost importance. In this video, we shed light on the various quality control measures implemented during the manufacturing process. From conducting regular inspections to testing the straps’ tensile strength, elongation, and impact resistance, we provide valuable insights into the rigorous testing procedures followed by reputable manufacturers.

Choosing the Right Supplier

When it comes to P.P strapping roll manufacturing plants and machines, choosing the right supplier is crucial. In this section, we discuss the key factors to consider when selecting a supplier. From assessing their industry experience and reputation to evaluating the quality of their machinery and after-sales support, we provide a comprehensive guide to help you make an informed decision.

FAQs

Throughout the video, we address common questions and concerns related to P.P strapping roll manufacturing. Some of the frequently asked questions include:

- What are the advantages of using P.P strapping rolls over other materials?

- What are the typical dimensions and specifications of P.P strapping rolls?

- How can I ensure the longevity of P.P strapping rolls?

- Can P.P strapping rolls be used with automatic strapping machines?

These FAQs provide valuable insights and solutions to common queries, helping viewers gain a deeper understanding of P.P strapping roll manufacturing.

Conclusion

Manufacturing P.P strapping rolls requires precision, expertise, and the right machinery. This video serves as a comprehensive guide, offering valuable insights into the manufacturing process, quality control measures, and considerations when choosing a supplier. Whether you are a manufacturer looking to improve your production or a user seeking high-quality P.P strapping rolls, this video provides the knowledge and information you need to make informed decisions.

Check the strapping machine solution with leading manufacturers for professional solutions just here.

#P.PStrappingRoll #ManufacturingPlant #StrappingMachine #P.PStrap #PlasticBand #QualityControl #SupplierSelection #FAQs