Tired of outdated, wasteful packaging in your coil packing lines? The mounting pressure to reduce environmental impact, coupled with rising material costs, demands a smarter approach. It’s time to explore innovative, sustainable packaging materials that protect your coils and the planet, without compromising your bottom line.

Sustainable packaging materials for coil packing lines focus on reducing environmental impact through recycled content, recyclability, reusability, and the use of renewable resources. Key options include high-recycled-content paper wraps, VCI (Vapor Corrosion Inhibitor) papers, recyclable PET (polyethylene terephthalate) strapping, steel strapping with recycled content, and engineered wood or composite pallets. These materials aim to provide robust protection while minimizing waste and carbon footprint in industrial settings.

The shift towards sustainability is no longer a niche concern but a fundamental aspect of modern manufacturing and logistics. For industries dealing with heavy and often sensitive products like metal coils, finding packaging solutions that are both effective and environmentally responsible is a critical challenge. This article will delve into the viable sustainable packaging materials available for coil packing lines, exploring their benefits, applications, and how they contribute to a more circular economy.

The Imperative of Green Packing in Industrial Coil Handling

The heavy-duty nature of coil packing has traditionally relied on materials often viewed as less than eco-friendly. With increasing global scrutiny on industrial waste and carbon footprints, the pressure is on to innovate. Adopting green packing strategies is not just about compliance; it’s about future-proofing your operations.

Green packing in industrial coil handling involves a strategic shift towards materials and processes that minimize environmental harm while ensuring product integrity. This means prioritizing options like VCI paper wraps made from recycled fibers, robust PET strapping with significant post-consumer resin content, steel strapping manufactured with a higher percentage of recycled steel, reusable dunnage, and lightweight yet durable alternatives to traditional wooden crating like engineered wood or corrugated board solutions. The goal is to reduce virgin material consumption, enhance recyclability, lower transportation emissions through lighter packaging, and ultimately decrease the overall environmental footprint of coil logistics without sacrificing protection against corrosion or physical damage during transit and storage.

Beyond the Buzzwords: Practical Sustainable Materials for Coils

The term "sustainable" can be broad, sometimes leading to confusion or "greenwashing." For coil packing lines, practical sustainability means tangible benefits in material sourcing, usage, and end-of-life management. It’s about measurable improvements, not just aspirational labels.

Recycled Content: The Backbone of Sustainable Coil Packaging

Utilizing materials with high recycled content is a cornerstone of sustainable packaging. This approach directly reduces the demand for virgin resources and diverts waste from landfills.

- Steel Strapping: Modern steel strapping often incorporates a significant percentage of recycled steel. This doesn’t compromise its tensile strength, crucial for securing heavy coils. The steel industry has well-established recycling infrastructures, making steel a highly circular material.

- PET Strapping: Polyethylene terephthalate (PET) strapping is a popular alternative to steel. Sustainable versions are available with high levels of post-consumer recycled (PCR) content. Recycled PET strapping maintains excellent strength and elongation properties, suitable for many coil applications, and is often lighter than steel, offering potential freight savings and reduced carbon footprint from transport.

- Paper and Board Wraps: Protective wraps made from kraft paper, linerboard, or corrugated board are increasingly incorporating recycled fibers. These can range from 100% recycled content to blends. Their effectiveness lies in providing a barrier against dust, moisture (when treated), and minor abrasions.

VCI Technology: Protection Meets Eco-Friendliness

Vapor Corrosion Inhibitor (VCI) technology is essential for protecting metal coils, especially those made of steel or aluminum, from rust and corrosion. Traditionally, this might have involved oils or coatings that pose disposal challenges.

- VCI Paper and Films: Modern VCI papers and films offer an eco-friendlier alternative. Many VCI papers are made with recycled content and are themselves recyclable after use (assuming they are not heavily contaminated). The VCI chemicals are designed to be safe and non-toxic. Some manufacturers are even exploring bio-based VCIs. The key benefit is dry protection, eliminating the need for messy, resource-intensive oiling and de-oiling processes.

- Water-Based VCI Coatings: For direct application or for coating packaging materials, water-based VCI coatings are preferable to solvent-based ones, reducing VOC (Volatile Organic Compound) emissions.

The Role of Paper and Board in Modern Coil Wrapping

Beyond just recycled content, paper and paperboard solutions are evolving for heavy-duty applications.

- Heavy-Duty Corrugated Board: Engineered corrugated solutions, sometimes triple-wall or custom-designed, can offer surprising strength and cushioning. They can be used for outer protection, interleaving, or even as components in pallet systems. They are lightweight, recyclable, and often made with a high percentage of recycled fibers.

- Honeycomb Paper Products: Materials like Curby Fill™ or Curby Wrap®, though often marketed for e-commerce, have industrial counterparts. Honeycomb paper structures provide excellent cushioning and void fill. For coil applications, they might be adapted for interleaving, edge protection, or internal bracing within larger crates, offering a recyclable alternative to foam.

- Molded Pulp: While less common for very large coils, molded pulp (made from recycled paper) can be custom-designed for smaller coils or components, providing excellent shock absorption. It’s biodegradable and compostable under industrial conditions.

| Feature | Traditional Material Examples | Sustainable Alternative Examples | Key Environmental Benefit | Performance Considerations for Coils |

|---|---|---|---|---|

| Strapping | Virgin Steel, Virgin Polypropylene | Steel with High Recycled Content, PET with PCR Content | Reduced virgin resource use, promotes circularity | Tensile strength, elongation, resistance to sharp edges |

| Corrosion Prot. | Heavy Oils, Solvent-based Coatings | VCI Paper (recycled content), VCI Film, Water-based VCI Coatings | Eliminates messy oils, reduces VOCs, often recyclable | Effectiveness, duration of protection, compatibility |

| Wrapping/Cover | Virgin Kraft Paper, Plastic Sheeting | Recycled Content Kraft/Linerboard, Heavy-Duty Corrugated | Reduces virgin fiber/plastic, diverts waste | Tear resistance, moisture barrier, puncture resistance |

| Pallet/Skid | Virgin Hardwood | Engineered Wood, Composite Pallets, Recycled Plastic Pallets | Reduces deforestation, utilizes waste streams | Load capacity, durability, moisture resistance |

| Cushioning | Polystyrene Peanuts, Foam Inserts | Honeycomb Paper, Molded Pulp, Corrugated Inserts | Biodegradable/recyclable, reduces plastic waste | Shock absorption, compression strength |

This shift isn’t just about individual materials but about a systemic approach. Optimizing package design to use less material overall ("right-sizing"), even if it’s a traditional material, is also a key sustainable strategy. For instance, an engineered packaging design might use less virgin steel strapping by optimizing its placement and tension, thereby reducing overall material consumption and weight.

Innovations Driving Eco-Friendly Options for Coil Packaging

The quest for greener coil packaging isn’t static; it’s fueled by material science breakthroughs and smarter design principles. As industries demand more sustainable and efficient solutions, innovators are rising to the challenge. The focus is on reducing reliance on virgin resources and enhancing end-of-life circularity.

Key eco-friendly innovations for coil packaging include advanced polymers for strapping with higher recycled content and improved strength, bio-based and biodegradable coatings (for specific, less demanding applications), and engineered paper products that offer enhanced moisture and tear resistance. Furthermore, modular and reusable packaging systems designed for closed-loop logistics are gaining traction, significantly reducing single-use packaging waste in coil transportation and handling.

Spotlight on Material Advancements and Design Strategies

The evolution of sustainable coil packaging hinges on two fronts: the development of new and improved materials, and the application of intelligent design strategies that maximize protection while minimizing environmental impact.

High-Strength Recycled PET Strapping

While PET strapping has been around, the innovation lies in incorporating higher percentages of Post-Consumer Recycled (PCR) content without compromising the critical properties needed for coil securement. Manufacturers are refining recycling processes and additive technologies to ensure that rPET (recycled PET) strapping delivers:

- Tensile Strength: Comparable, in many cases, to virgin PET and even some lighter grades of steel strapping.

- Elongation and Recovery: Essential for maintaining tension around coils that might settle or shift.

- Consistency: Ensuring that the rPET material performs reliably from batch to batch.

The environmental win is significant, as it reduces reliance on virgin petrochemicals and diverts plastic waste from landfills. Additionally, PET is generally lighter than steel, which can contribute to lower transportation emissions.

Advanced Paper-Based Wraps and Liners

Paper, a renewable resource, is seeing a resurgence with technological enhancements. For coil packaging, this means:

- Improved Moisture Resistance: Traditional paper is susceptible to moisture. New coatings (often water-based and repulpable) and lamination techniques (e.g., with bio-films) are improving paper’s ability to protect coils in humid environments or from incidental water contact. Some solutions, like "Curby Mailers" for e-commerce, showcase innovative paper cushioning; industrial equivalents are emerging for surface protection and interleaving.

- Enhanced Strength and Durability: Through specialized fiber treatment, cross-lamination, and reinforcement (sometimes with natural fibers or recyclable scrims), paper wraps are becoming tougher and more resistant to tears and punctures, making them suitable for more demanding applications in coil handling.

- VCI Integration: VCI chemicals are effectively integrated into paper, providing a dry, clean method of corrosion prevention. Innovations here focus on more efficient VCI release, longer-lasting protection, and the use of VCI formulations that are even more environmentally benign.

Reusable and Modular Packaging Systems

The ultimate form of sustainable packaging is often reusable packaging. For B2B coil transport, particularly in closed-loop or well-defined supply chains, reusable systems offer substantial waste reduction:

- Returnable Steel or Plastic Pallets/Cradles: Designed for durability and multiple trips, these can replace single-use wooden skids. While the initial investment is higher, the per-trip cost can be lower over time.

- Modular Dunnage: Instead of custom-cut wood or foam dunnage for each shipment, modular and adjustable dunnage made from durable recycled plastics or composites can be adapted for various coil sizes.

- Leasing/Pooling Systems: Third-party companies often manage pools of reusable transport packaging, handling logistics, cleaning, and repair, making adoption easier for coil manufacturers and end-users.

The Cautionary Tale of "Greenwashing" in Industrial Packaging

As sustainability becomes a selling point, it’s crucial to be wary of "greenwashing" – misleading claims about a product’s environmental benefits. When evaluating sustainable packaging for coils:

- Look for Certifications: Third-party certifications (e.g., FSC for paper from responsible sources, recycled content verification) provide credibility.

- Question Vague Claims: Terms like "eco-friendly" or "green" without specific, verifiable attributes should be scrutinized. Ask for data on recycled content percentage, recyclability in your local infrastructure, or biodegradability conditions.

- Consider the Full Life Cycle: A material might be "biodegradable" but only under specific industrial composting conditions not readily available. Or it might be "recyclable" but not if contaminated with oils or adhesives typical in coil applications. The overall impact, from raw material extraction to disposal or recycling, matters.

- Focus on Genuine Reduction: Sometimes, the most sustainable option is simply using less material through better design, even if the material itself isn’t novel.

By focusing on genuine material advancements and holistic design strategies, the coil packing industry can make significant strides in reducing its environmental footprint without compromising the crucial task of product protection.

Implementing Sustainable Materials: A Technical Deep Dive for Coil Lines

Transitioning your coil packing line to sustainable materials sounds promising, but the practicalities can seem daunting. Concerns about operational disruptions, material compatibility, or performance trade-offs are valid. However, a strategic and well-planned implementation can ensure a smooth switch with tangible benefits.

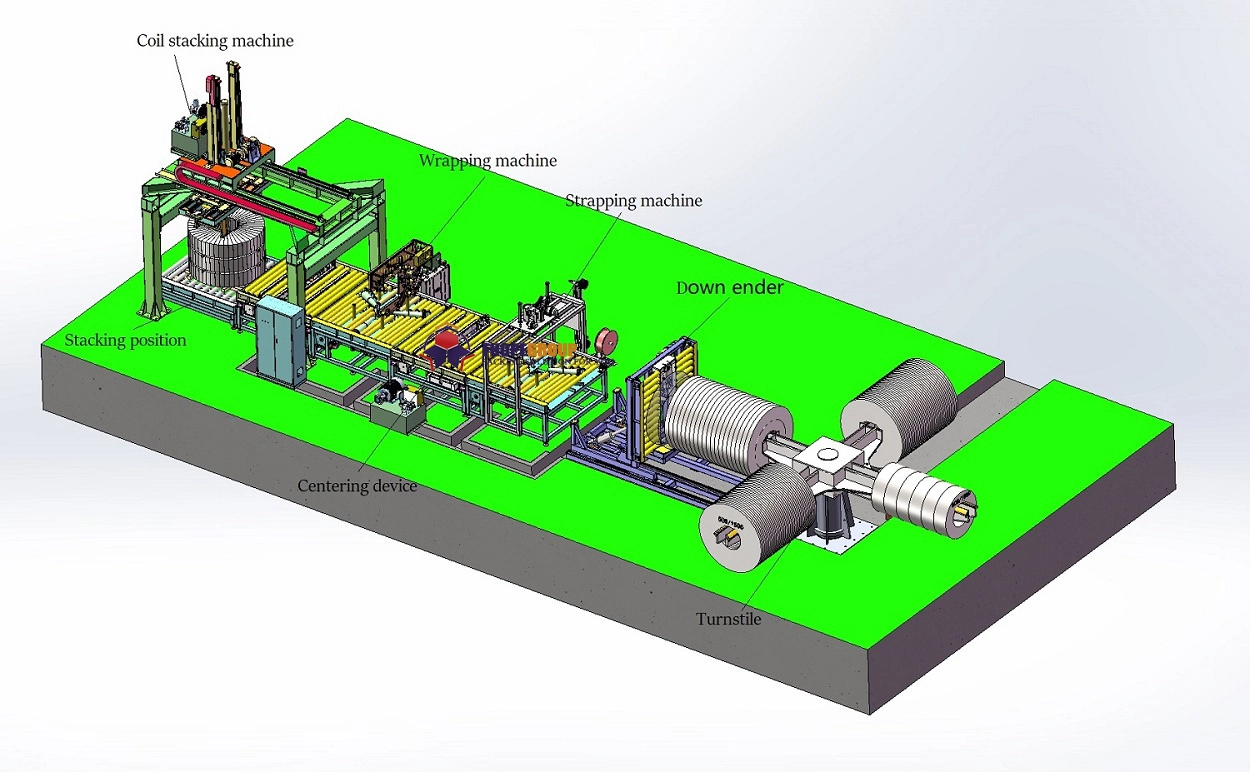

Successful adoption of sustainable packaging in coil lines involves rigorous material testing for strength and protective qualities, thorough compatibility checks with existing automated or semi-automated coil packing machines, careful supply chain adjustments for sourcing new materials, and a comprehensive cost-benefit analysis. This ensures that both performance integrity for the coils and overarching sustainability goals are effectively met without unforeseen operational hurdles.

Operationalizing Sustainability: From Sourcing to End-of-Life

Making the switch to sustainable packaging materials is more than just ordering a new type of wrap or strapping. It requires a holistic view of your coil packing operations.

Assessing Material Performance for Coils

Before a full-scale rollout, any new sustainable material must be rigorously tested to ensure it meets the specific demands of your coils and logistics chain.

- Strength and Durability Testing:

- Strapping: Tensile strength, elongation, break strength, and joint efficiency (for seals or welds) are critical. For coils, resistance to edge damage and creep (gradual stretching under sustained load) must be evaluated.

- Wraps/Covers: Tear resistance, puncture resistance, and burst strength. If VCI is incorporated, its effectiveness over time and under various atmospheric conditions needs validation.

- Cushioning/Dunnage: Compression strength and shock absorption capabilities.

- Environmental Resistance: Evaluate performance under varying temperature and humidity conditions expected during storage and transit. For VCI materials, test their corrosion-prevention efficacy on actual coil surfaces.

- Compatibility with Coils: Ensure the packaging material does not react adversely with the coil material (e.g., staining, chemical interaction). This is particularly important for finished or sensitive surfaces.

Integrating New Materials into Existing Packing Lines

A key concern is how new materials will run on existing equipment.

- Strapping Machines: If switching from steel to PET strapping, or to a different type of PET, adjustments to tensioners, sealers (friction-weld vs. heat-seal), and dispensers might be needed. Trial runs are essential to check for feeding issues, consistent sealing, and appropriate tension application.

- Wrapping Equipment: For stretch wrappers or spiral wrappers, the new paper or film material’s elasticity, cling (if applicable), and tear resistance during application are important. Dispensing systems may also need adjustment for different roll widths or core sizes.

- Manual Processes: Even for manual application, consider ergonomics and ease of use for operators. Lighter materials might improve handling, but different textures or stiffness could require new techniques.

Life Cycle Assessment (LCA) Considerations

A true understanding of sustainability involves looking at the entire life cycle of the packaging material.

- Sourcing: Where do the raw materials (virgin or recycled) come from? What is the environmental impact of their extraction and processing? Prioritizing domestic or regional manufacturing, as EcoEnclose does for its products, can reduce transportation emissions and support local economies if applied to industrial material sourcing.

- Manufacturing: What is the energy consumption and waste generation associated with producing the packaging material itself?

- Use Phase: Consider durability and reusability if applicable.

- End-of-Life: Is the material genuinely recyclable in the regions where your coils are unpacked? Are there clear instructions for disposal (e.g., How2Recycle® labeling, though more common in CPG, the principle applies)? If compostable, are appropriate facilities available? For industrial packaging, contamination can be a major barrier to recycling, so ease of separation or resistance to contamination is a plus.

| Implementation Stage | Key Activities | Potential Challenges | Mitigation Strategies |

|---|---|---|---|

| 1. Material Evaluation | Lab testing (strength, VCI), pilot trials on non-critical coils, supplier audits. | Material underperformance, incompatibility with coil surface, insufficient VCI protection. | Define clear performance specs, test under realistic conditions, work closely with reputable suppliers. |

| 2. Equipment Adaptation | Trial runs on packing lines, calibration of tensioners/sealers, modification of dispensers/applicators. | Feeding issues, inconsistent seals, equipment downtime, need for new machinery. | Phased trials, involve equipment manufacturers, operator training, consider modular equipment upgrades. |

| 3. Supply Chain & Cost | Identify reliable suppliers, negotiate pricing, analyze total cost of ownership (material, labor, disposal). | Availability issues, price volatility, higher upfront material cost. | Diversify suppliers, long-term contracts, factor in savings from reduced damage/waste, lighter shipping weights. |

| 4. Training & SOPs | Develop new Standard Operating Procedures (SOPs), train operators on new materials and equipment settings. | Operator resistance to change, incorrect material application leading to failures. | Clear communication of benefits, hands-on training, visual aids, regular performance feedback. |

| 5. End-of-Life Mgmt. | Investigate recycling/disposal options for customers, provide guidance, explore take-back programs. | Lack of recycling infrastructure at customer end, contamination issues. | Partner with waste management providers, design for disassembly, use clearly marked recyclable materials. |

Successfully implementing sustainable packaging materials in coil lines is an iterative process. It requires commitment from management, collaboration between engineering, procurement, and operations teams, and strong partnerships with material suppliers. The long-term benefits—reduced environmental impact, potential cost savings, and enhanced brand reputation—make it a worthwhile endeavor.

The Business Case: Why Sustainable Coil Packaging is Smart Business

Adopting sustainable packaging materials for your coil packing lines isn’t just an environmental obligation; it’s increasingly a strategic business decision with tangible benefits. Moving beyond the "cost of going green" mindset reveals opportunities for cost savings, enhanced brand reputation, and a stronger competitive edge in a market that increasingly values corporate responsibility.

The business case for sustainable coil packaging rests on several pillars: reduced operational costs through material optimization, lighter shipping weights, and minimized waste disposal fees; enhanced brand reputation and customer loyalty by meeting growing demands for environmental responsibility; improved access to markets with stringent green regulations; and increased employee engagement driven by a shared commitment to sustainability. These factors contribute to long-term profitability and resilience. This strategic shift aligns with how cutting-edge brands across various sectors, like those highlighted by EcoEnclose (Ritual, Stio, Cocofloss), leverage sustainability not just for ecological good but for brand differentiation and customer connection, a principle equally applicable to the B2B industrial space.

Cost Savings Through Material Optimization and Waste Reduction

While some sustainable materials might have a higher upfront purchase price per unit, a holistic view often reveals significant cost-saving opportunities:

- Reduced Material Consumption: Innovative sustainable materials can be stronger or more efficient, allowing for the use of less material overall to achieve the same level of protection (e.g., thinner gauge VCI paper with higher efficacy, or optimized PET strapping configurations). This directly translates to lower material purchase costs.

- Lower Shipping Costs: Lighter packaging materials, such as PET strapping instead of steel, or engineered corrugated board instead of heavy wooden crates, reduce the overall weight of the shipped product. This can lead to substantial savings in freight costs, especially for long-distance or international shipments.

- Minimized Waste Disposal Fees: Using recyclable materials can reduce the volume of waste sent to landfills, thereby lowering disposal fees for both your facility and potentially your customers’. Reusable packaging systems, over their lifespan, can drastically cut down on single-use packaging waste and associated costs.

- Reduced Product Damage: Effective sustainable packaging, particularly those incorporating advanced VCI technology or superior cushioning, can lead to lower rates of product damage from corrosion or transit impacts. This avoids the costs associated with returns, rework, or scrapped coils.

- Increased Operational Efficiency: Some sustainable solutions might be easier or faster to apply, potentially reducing labor costs or increasing throughput on the packing line. For example, VCI paper can eliminate time-consuming oiling and de-oiling processes.

Enhancing Brand Image and Market Access

In today’s environmentally conscious world, a commitment to sustainability can be a powerful differentiator:

- Improved Corporate Reputation: Companies that proactively adopt green practices are often viewed more favorably by customers, investors, and the public. This can enhance brand loyalty and attract new business.

- Meeting Customer Demands: Increasingly, B2B customers, especially large corporations, have their own sustainability targets and are scrutinizing the environmental performance of their suppliers. Using sustainable packaging can help you meet these procurement requirements and maintain preferred supplier status.

- Access to New Markets: Some markets or regions have stricter environmental regulations or a stronger consumer preference for sustainable products. Eco-friendly packaging can be a key enabler for entering or expanding in these areas.

- Attracting and Retaining Talent: Employees, particularly younger generations, are often drawn to companies with strong ethical and environmental values. A visible commitment to sustainability can boost morale and aid in talent acquisition and retention.

Navigating Regulatory Landscapes and Future-Proofing

The regulatory environment concerning packaging waste and environmental impact is constantly evolving and generally becoming more stringent:

- Compliance with Existing and Upcoming Regulations: Extended Producer Responsibility (EPR) schemes, plastic taxes, and landfill restrictions are becoming more common globally. Adopting sustainable packaging proactively can help ensure compliance and avoid potential penalties or operational disruptions. The "Guide to Extended Producer Responsibility" mentioned in the source material highlights the growing complexity brands face, which applies to industrial goods as well.

- Anticipating Future Trends: The push for a circular economy is gaining momentum. Businesses that invest in sustainable packaging now will be better positioned to adapt to future requirements and market expectations, gaining a first-mover advantage.

- Tariff Resilience and Supply Chain Transparency: While not always directly tied to "sustainability," prioritizing domestic or regional sourcing for recycled content or packaging manufacturing, as noted by EcoEnclose’s emphasis on domestic manufacturing, can build resilience against global trade disruptions and improve supply chain transparency, which are valuable business assets.

By viewing sustainable packaging through a strategic business lens, companies in the coil industry can uncover opportunities to not only reduce their environmental impact but also to strengthen their financial performance, enhance their market position, and build a more resilient and reputable enterprise.

Conclusion

The transition to sustainable packaging materials for coil packing lines is an essential evolution for the industry. It’s a multifaceted approach that balances the critical need for robust product protection with the growing imperative for environmental stewardship. From high-recycled-content steel and PET strapping to innovative VCI papers and engineered paper-based solutions, viable and effective options are increasingly available. Embracing these Sustainable Materials not only mitigates environmental impact through reduced waste and lower carbon footprints but also offers tangible business benefits, including potential cost savings, enhanced brand reputation, and improved regulatory compliance. As technology and material science continue to advance, the future of coil packing will undoubtedly be greener and more circular.