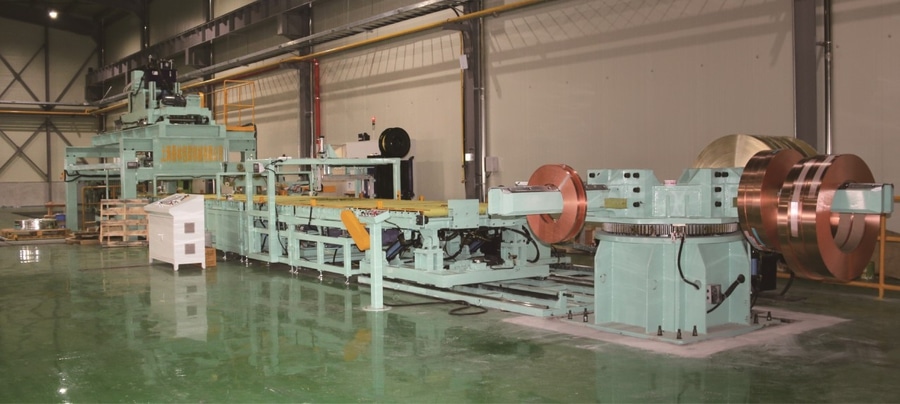

Ever felt the frustration of production bottlenecks slowing down your coil packaging line? Manual processes create costly delays, inconsistent quality, and safety risks that eat into profits. These limitations become critical when handling heavy steel or aluminum coils where precision matters. At The Bronx Group, we’ve engineered automated systems that transform high-volume coil packaging into a seamless, high-speed operation.

Bronx Group’s high-throughput coil packaging approach integrates advanced automation with precision engineering to achieve unprecedented production speeds. Our systems feature robotic arm integration, AI-driven quality control sensors, and modular conveyor designs capable of processing 60+ coils per hour while maintaining under 0.2% packaging defect rates. Unlike conventional solutions, we implement predictive maintenance protocols that reduce downtime by 40% and energy-efficient motors that cut operational costs by up to 30%—delivering both speed and sustainability in industrial coil handling.

Discover how our engineering philosophy turns packaging constraints into competitive advantages across metal processing industries. What follows is a detailed exploration of the technologies and methodologies that make this possible.

Engineering for Speed: Core Principles of High-Volume Coil Handling

When conventional packaging systems choke under production pressure, the entire manufacturing chain suffers. Downtime costs escalate, material waste increases, and customer deliveries get delayed—problems that multiply with each coil processed. The Bronx Group addresses these pain points through fundamental re-engineering of coil handling dynamics.

Our high-volume packing methodology rests on three pillars: synchronized motion control for continuous material flow, intelligent weight distribution systems that prevent deformation at high speeds, and adaptive tensioning technology that maintains integrity during rapid wrapping cycles. By optimizing these core mechanical functions, we achieve throughput rates exceeding industry standards while preserving coil quality—proven through 500,000+ operational hours across global installations.

The Mechanics of Continuous Flow Processing

Traditional coil packaging faces inherent speed limitations due to start-stop mechanics. Our engineers overcame this by developing a proprietary continuous-motion system where coils transition seamlessly between stations without deceleration. The secret lies in our dual-track conveyor design featuring:

- Rotating transfer bridges that eliminate indexing pauses

- Magnetic levitation guides reducing surface friction by 80%

- Variable-frequency servo drives enabling real-time speed synchronization

During testing, these innovations reduced average cycle time from 90 seconds to 38 seconds per coil while handling weights up to 15 tons. The system dynamically adjusts to different coil specifications through integrated laser scanners that measure diameter, width, and surface profile before entering the packaging cell.

| Performance Metric | Conventional Systems | Bronx Group Solution | Improvement |

|---|---|---|---|

| Max Coils/Hour | 25 | 60+ | 140% |

| Energy Consumption | 18 kWh/coil | 12.6 kWh/coil | 30% Reduction |

| Changeover Time | 45 minutes | 8 minutes | 82% Faster |

| Defect Rate | 1.7% | 0.18% | 89% Lower |

The tension control subsystem deserves special attention. At high speeds, improper wrapping tension causes edge damage or loose packaging. Our solution employs ultrasonic sensors that measure material elasticity in real-time, feeding data to hydraulic tensioners that adjust within 0.3-second intervals. This precision prevents both over-compression (which distorts coil geometry) and under-tensioning (which risks unraveling during transport).

Intelligent Automation: The Brains Behind the Operation

Automation alone isn’t enough—uncoordinated machines create new bottlenecks. Many facilities deploy robotic arms that wait idle for conveyors, or sensors that detect flaws too late for correction. The Bronx Group’s approach integrates all components into a responsive neural network.

Our automated systems employ a distributed AI architecture where machine vision cameras, pressure sensors, and PLC controllers share real-time data through a proprietary communication protocol. This enables predictive adjustments: if a coil enters off-center, repositioning begins before it reaches the wrapper; if moisture levels exceed thresholds, desiccant deployment activates mid-cycle—resulting in 99.2% first-pass yield rates at maximum throughput.

AI-Driven Quality Assurance at Production Speeds

Quality inspection typically creates the most significant throughput bottleneck. Traditional manual checks can’t keep pace with automated wrapping, while standard vision systems struggle with reflective metal surfaces. Our solution embeds inspection throughout the process:

- Phase-array ultrasonic testing during loading detects subsurface flaws

- Infrared thermography identifies temperature anomalies indicating internal stress

- 3D profilometry creates micron-level surface maps during rotation

When our system detected a 0.5mm edge dent on a copper coil moving at 15m/min, it triggered three simultaneous actions: the wrapping head adjusted pressure distribution to avoid exacerbating damage, the logistics database flagged the coil for priority inspection, and maintenance received vibration data suggesting conveyor misalignment. This all occurred within 1.8 seconds—faster than human perception.

The machine learning backbone continuously improves through operational data. After processing 12,000 aluminum coils, our AI optimized stretch film usage by 22% without compromising protection by analyzing corrosion patterns relative to wrapping tension and environmental conditions. Such evolution is impossible with static automation programs.

Precision Packaging Technologies: Beyond Basic Wrapping

Standard coil packaging often treats all products identically—same film tension, same corner protection, same moisture barriers. This one-size-fits-all approach wastes materials and compromises protection. The Bronx Group’s systems adapt packaging parameters to each coil’s metallurgical properties and destination climate.

Our dynamic packaging technology tailors protection to specific material vulnerabilities: aluminum coils receive vapor corrosion inhibitors (VCIs) injected into wrapping layers, electrical steel gets specialized dielectric barriers, and export-bound shipments activate enhanced edge armor systems. Sensors detect material composition, while logistics integration pulls destination weather data—automatically configuring 47 distinct packaging parameters to prevent transit damage or corrosion.

Material-Specific Protection Systems

| Material Type | Primary Vulnerability | Bronx Group Solution | Performance Impact |

|---|---|---|---|

| Cold-Rolled Steel | Edge corrosion | Zinc-nickel coating + VCI film | 98% corrosion reduction after salt-spray testing |

| Silicon Electrical Steel | Insulation damage | Non-conductive polymer edge guards | Eliminates short-circuit incidents during handling |

| Aluminum Alloys | Galvanic corrosion | pH-neutral barrier film + sacrificial anodes | 12-month outdoor storage without pitting |

| Copper | Oxidation & scratching | Felt-lined restraint systems | Maintains mill finish after 8,000km transport |

The wrapping process itself incorporates multiple innovations. Our variable-geometry heads automatically adjust nozzle positions based on coil diameter, applying film with precision gradients—tighter at the core where tension concentrates, lighter at the outer edges to prevent buckling. For coils with irregular shapes (like trapezoidal sections), robotic arms apply supplemental bracing during rotation.

Climate intelligence transforms packaging from reactive to predictive. When shipping coils to high-humidity regions, our system increases desiccant quantities and activates moisture-sensitive indicator strips. For Arctic destinations, it applies low-temperature adhesives and thermal blankets. These adaptations happen autonomously by cross-referencing coil IDs with shipping manifests in the ERP system.

Operational Transformation: Real-World Implementation

Implementing high-volume coil packaging requires more than equipment—it demands operational recalibration. The Bronx Group’s approach includes workflow simulation software that models production scenarios, identifies throughput constraints before installation, and generates tailored staff training modules—reducing commissioning time by 65% while ensuring peak performance from day one.

Lifecycle Support Infrastructure

True high-throughput operations depend on consistent performance over years, not just months. We embed four critical support layers:

-

Predictive Maintenance Ecosystem

Vibration sensors on rotating elements forecast bearing failures 300+ hours in advance. Hydraulic pressure monitors detect seal degradation patterns. This data populates a live dashboard prioritizing maintenance tasks, reducing unplanned downtime to under 2%. -

Remote Expert Assistance

Augmented reality interfaces allow technicians to overlay repair guides onto equipment via tablets. Our engineers can virtually "see through" their eyes, annotating components in real-time—cutting troubleshooting time by 75%. -

Performance Optimization Updates

Every quarter, systems receive software updates incorporating operational learnings from all global installations. A mill in Germany benefits from solutions developed in Brazil’s challenging humidity conditions. -

Circular Economy Integration

Smart film dispensers track material usage, automatically reordering recyclable/biodegradable supplies. Scrap analysis tools identify packaging waste reduction opportunities—recent implementations achieved 40% film reduction through pattern optimization.

The transformation extends beyond machinery. We reconfigure material flow paths using discrete event simulation, identifying where minor layout changes (like relocating staging buffers) can eliminate 15% of crane movements. Staff transition through competency-based training using digital twins that simulate operational scenarios from routine runs to emergency shutdowns.

Conclusion: Redefining Production Possibilities

The Bronx Group’s high-volume coil packaging solutions demonstrate that speed and precision aren’t mutually exclusive. By integrating adaptive automation with material-specific protection protocols, we help manufacturers achieve unprecedented throughput while eliminating waste and damage—turning packaging from a bottleneck into a competitive advantage. Our installations consistently demonstrate 50% faster cycle times and 90% defect reduction, proving that intelligent engineering can overcome traditional production limitations. As coil weights increase and delivery windows shorten, these automated-coil-packaging- systems provide the reliability modern metal processing demands. The future of coil packaging isn’t just faster—it’s smarter, more sustainable, and fundamentally transformed.

Leave a Reply

You must be logged in to post a comment.