Decoding Coil Packing Line Terminology: A Glossary for Buyers

Navigating the world of coil packing lines can feel like learning a new language, filled with technical jargon and specialized terms. This complexity can often leave buyers feeling apprehensive, unsure if they’re making the right investment. This comprehensive glossary is your Rosetta Stone, designed to demystify the terminology.

A coil packing line terminology glossary for buyers is an essential reference guide that defines and explains the specialized vocabulary related to machinery, materials, processes, and quality control in automated coil packaging systems. This empowers buyers to understand proposals, compare vendor offerings accurately, articulate their needs precisely, and ultimately select a coil packing solution that enhances efficiency, protects products, and delivers a strong return on investment.

Stepping into the realm of industrial coil packing lines without a firm grasp of the lingo can be a daunting prospect. You’re not just buying machinery; you’re investing in a critical part of your production and logistics chain. Misinterpreting a single term could lead to a mismatched system, operational inefficiencies, or even damaged products down the line. This glossary aims to bridge that knowledge gap, transforming you from a cautious inquirer into a confident, well-informed buyer. Let’s decode the language of coil packing together, ensuring your next investment is a strategic success.

Core Coil Packing Machinery Terms Explained

Investing in a coil packing line means encountering a host of machinery-specific terms. Overlooking or misinterpreting these can lead to selecting equipment ill-suited for your needs, impacting efficiency and budget. This section demystifies these critical machinery terms, empowering you to make informed purchasing decisions.

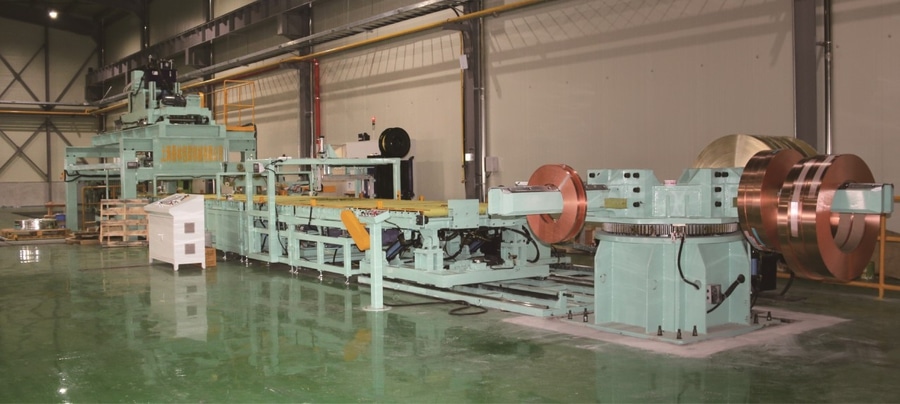

Core coil packing machinery terms refer to the various integrated pieces of equipment that handle, process, and package coils, such as coil cars, uncoilers, straighteners, slitters, tension stands, recoilers, strapping machines (both circumferential and radial), wrapping machines (utilizing eye-to-sky or through-the-eye methods), coil tilters/upenders, stackers, and palletizing systems. A clear understanding of each component’s specific function—from the initial manipulation and preparation of the coil to its secure strapping, protective wrapping, and final automated stacking or palletizing for shipment—is absolutely essential for buyers. This knowledge allows for the precise specification of operational requirements, accurate comparison between different supplier offerings, and ensures the acquired machinery aligns perfectly with production goals and product characteristics, leading to a more robust and efficient packing operation.

In-Depth Look at Key Coil Packing Machinery Components

To truly master the art of purchasing a coil packing line, a deeper dive into the primary machinery components is essential. Each piece of equipment plays a pivotal role, and understanding their nuances, capabilities, and interdependencies can significantly influence your line’s overall performance and efficiency.

H3: Coil Handling and Preparation Equipment

The journey of a coil through a packing line begins with precise handling and preparation.

- Coil Car (or Coil Loading Car): This is a transfer device used to safely and efficiently load coils onto the uncoiler/decoiler mandrel. It typically moves on rails and can lift the coil to the correct height for mandrel insertion. Key considerations include weight capacity, lift height, and traverse speed. Some are simple hydraulic lifts, while others offer powered rotation for easier alignment.

- Uncoiler (or Decoiler): The uncoiler is responsible for holding the master coil and unwinding it in a controlled manner for subsequent processing.

- Mandrel: The expanding spindle that grips the inner diameter (ID) of the coil. Types include link-type (segmental) or wedge-type a. Mandrel expansion can be manual, hydraulic, or electric.

- Single Mandrel Uncoiler: Features one mandrel. Requires downtime for loading new coils.

- Double Mandrel (Turret) Uncoiler: Features two mandrels on a rotating turret. While one coil is being processed, another can be loaded onto the spare mandrel, significantly reducing changeover time.

- Non-Contact Loop Control: Uses sensors (e.g., ultrasonic, laser) to monitor the slack of the unwinding strip, controlling the uncoiler’s speed to prevent tension issues or material damage.

- Brake System: Essential for preventing coil over-spin and maintaining proper back tension. Can be pneumatic, hydraulic, or electric.

- Peeler Table/Pinch Rolls: Assists in feeding the leading edge of the coil strip from the uncoiler into the next processing station, especially for heavier gauge or high-strength materials.

- Coil Straightener/Flattener (Less Common in Pure Packing Lines): While more prevalent in processing lines, a straightener might be included if minor shape correction is needed before certain packing steps for specific coil types. It uses a series of offset rollers to remove coil set or curvature.

H3: Strapping Machines – Securing the Coil

Strapping is fundamental to maintaining coil integrity and facilitating safe handling. The choice between circumferential and radial strapping, and the strapping head technology, depends heavily on the coil type and downstream requirements.

- Circumferential Strapping (Eye-to-Wall or Eye-to-Periphery): Straps are applied around the coil’s circumference, passing through the eye. This prevents the coil from unwinding or "clock-springing" and helps maintain its round shape.

- Number of Straps: Varies based on coil width and weight; typically 2 to 6 straps.

- Strap Placement: Evenly spaced across the coil width.

- Radial Strapping (Eye-to-Sky or Eye-to-Face): Straps are applied across the faces of the coil, passing over the outside diameter and through the eye. This helps secure the coil layers together, preventing telescoping, and can provide lifting points.

- Number of Straps: Typically 3, 4, or 6 straps, often at 120°, 90°, or 60° intervals around the coil.

-

Strapping Head Technologies: The heart of the strapping machine, responsible for tensioning, sealing, and cutting the strap.

Feature Pneumatic Strapping Heads Electric (Servo) Strapping Heads Hydraulic Strapping Heads Power Source Compressed Air Electricity Hydraulic Fluid Tension Control Good, but can vary with air pressure Precise, Electronically Programmable High, Variable, Powerful Maintenance Moderate (seals, cylinders) Lower (fewer moving parts) Higher (hoses, fluid, seals) Cycle Speed Fast Very Fast, Programmable Moderate Initial Cost Lower Higher Highest Operating Cost Moderate (air consumption) Lower (energy efficient) Moderate (hydraulic power unit) Seal Type Notch, Friction Weld, Buckle Friction Weld, Ultrasonic Notch, Sealless (Punch) Common Materials Steel, Heavy-Duty PET PET, PP Primarily Steel (High-Tensile) Environment Robust, can be oily/dirty Cleaner operations preferred Can be robust, potential leaks Fabricator’s Focus: Electric servo strapping heads are increasingly favored for their precision, energy efficiency, and reduced maintenance, especially with PET strapping. However, for very heavy coils requiring extreme tension, steel strapping with pneumatic or hydraulic heads remains a go-to solution.

H3: Wrapping Machines – Protecting the Product

Wrapping provides a crucial barrier against environmental factors and physical damage.

- Eye-to-Sky (Orbital) Wrapping Machine: The coil rests with its eye facing upwards. The wrapping material (e.g., stretch film, VCI paper) is dispensed from a shuttle that orbits around the OD and through the ID of the coil. Offers excellent full-surface protection.

- Through-the-Eye (Eye-to-Wall) Wrapping Machine: The coil rests typically with its eye horizontal. The wrapping material is applied as the coil rotates on rollers or a turntable, with the material fed through the eye and around the circumference.

- Stretch Wrapping: Utilizes stretch film to tightly bind and protect the coil.

- Film Carriage System: Controls the pre-stretch of the film, maximizing yield and holding force.

- Paper Wrapping: Often involves VCI (Volatile Corrosion Inhibitor) paper to protect against rust, or kraft paper for physical protection.

- Combination Wrapping: Some machines can apply multiple layers of different materials (e.g., VCI paper followed by stretch film).

H3: Coil Positioning and Orientation

- Coil Tilter/Upender: Mechanical or hydraulic devices used to change the orientation of the coil, for example, from eye-to-sky (vertical eye) to eye-to-wall (horizontal eye) or vice-versa, to suit different processing or packaging machines. This is critical for lines handling coils in various orientations.

H3: Stacking, Palletizing, and Dispatch Systems

The final stages prepare the packed coils for storage or shipment.

- Stacking Systems: Automated systems that take individual packed coils and stack them to a predetermined height. Can involve robotic arms or gantry systems.

- Dunnage Insertion: May include automated placement of wooden blocks or other separating materials between stacked coils.

- Palletizing Systems: Arrange and place coils or stacks of coils onto pallets or skids.

- Pallet Dispensers: Automatically feed empty pallets into the system.

- Sheet Dispensers: Place protective sheets (e.g., cardboard, plastic) on the pallet before coil loading or between layers.

- Conveyor Systems: Transport coils between different stations in the packing line. Types include roller conveyors, chain conveyors, and belt conveyors.

- Weighing Stations: Integrated scales to record the weight of finished packs for shipping documentation and quality control.

- Labeling Systems: Automatically apply labels with product information, tracking barcodes, and shipping details to the packed coils or pallets.

Understanding these core machinery components and their variations allows buyers to engage more effectively with suppliers, clearly define their requirements, and select a coil packing line that is truly optimized for their specific products and operational environment.

Navigating Material and Consumable Terminology in Coil Packing

The machinery is only one part of the equation; the materials and consumables used in your coil packing line are equally critical. Choosing incorrectly can compromise product integrity or inflate operational costs. This section will illuminate the key terms associated with these essential packing elements.

Key material and consumable terms in coil packing include VCI (Volatile Corrosion Inhibitor) paper or film, stretch film (LLDPE, cast, or blown), strapping (steel, PET, or PP), corner/edge protectors (cardboard, plastic, or metal), interleaving materials (paper, foam), dunnage (wood, plastic), and various adhesives or tapes. Familiarity with these terms ensures appropriate selection for corrosion prevention, abrasion resistance, and load stability during handling and transit.

Choosing the Right Protective Materials: A Buyer’s Guide

Selecting the optimal protective materials is paramount to ensuring your coils arrive at their destination in pristine condition. The choice of materials isn’t just about wrapping or strapping; it’s about creating a protective ecosystem around your valuable product. This involves understanding the properties of different consumables and how they interact with your coil and the environment it will face.

-

VCI (Volatile Corrosion Inhibitor) Technology:

- How it Works: VCI materials (paper, film, emitters) release a vapor that forms a microscopic protective layer on metal surfaces, inhibiting the electro-chemical reactions that cause corrosion. This is a "dry" protection method, meaning no oils or greases are directly applied to the coil.

- Types:

- VCI Paper: Kraft paper impregnated with VCI chemicals. Often used for interleaving or wrapping.

- VCI Film: Polyethylene film embedded with VCI. Available as stretch film, shrink film, or bags. Offers moisture barrier in addition to corrosion protection.

- VCI Emitters/Diffusers: Small devices (chips, foams, powders in sachets) that release VCI vapor within an enclosed space, like a crated coil.

- Considerations: The type of VCI is chosen based on the metal type (ferrous, non-ferrous, multi-metal), duration of protection required, and the packaging design. Ensure the VCI is compatible with your specific metal. The volume of the enclosed space and the desired protection lifespan dictate the amount of VCI material needed.

-

Stretch Film (Load Containment Film):

- Primary Purpose: To unitize coils on a pallet, secure protective layers, and offer resistance to dust, moisture, and minor abrasions.

- Types & Properties:

- Cast Stretch Film: Known for clarity, quiet unwind, and good cling. Generally less puncture-resistant than blown film.

- Blown Stretch Film: Higher puncture and tear resistance, excellent cling, but can be noisy to unwind and less clear.

- Gauge (Thickness): Measured in microns or mils. Heavier, unstable loads require thicker film. Common gauges range from 60-120 gauge (15-30 microns).

- Pre-Stretch: The process of elongating the film before application. Modern wrappers can pre-stretch film by 200-300%, significantly reducing film consumption and increasing load-holding force.

- Application Methods: By machine (orbital wrappers, turntable wrappers) or manually (less common for coils due to size/weight).

-

Strapping Materials – The Backbone of Coil Security:

- Steel Strapping:

- Properties: Highest tensile strength, minimal elongation. Ideal for very heavy, sharp-edged, or hot coils.

- Grades: Regular duty (RD) and high-tensile (HT).

- Finishes: Painted/waxed for corrosion resistance and easier feeding.

- Sealing: Notch seals, seal-less (punch) joints, or weld seals.

- Downsides: Can rust if not protected, sharp edges can damage coils or be a safety hazard if not handled correctly. Edge protectors are often mandatory.

- PET (Polyester) Strapping:

- Properties: High strength (approaching steel in some grades), excellent tension retention, good elongation and recovery. Does not rust, safer to handle than steel.

- Applications: Increasingly replacing steel for many coil applications due to cost-effectiveness and safety. Suitable for coils that might settle or shrink.

- Sealing: Typically friction weld or heat seal.

- PP (Polypropylene) Strapping:

- Properties: Lighter duty, higher elongation, lower cost. Good for bundling lighter items or less demanding coil applications. Loses tension more readily than PET or steel.

- Applications: Securing protective layers, bundling small, light coils, or as a secondary strapping material.

- Sealing: Heat seal or friction weld, also metal buckles.

- Steel Strapping:

-

Corner Protectors / Edge Guards:

- Purpose: Distribute strapping tension over a wider area to prevent the strap from cutting into or damaging the coil edges. Essential when using steel strapping on softer metals or coated coils. Also helps maintain pack shape.

- Materials:

- Cardboard/Fibreboard: Most common, economical, recyclable. Available in various thicknesses and lengths.

- Plastic (PE, PP, PET): More durable, moisture-resistant, reusable. Can be rigid or flexible.

- Metal (Steel/Aluminum): For very heavy-duty applications or when sharp edges are a major concern.

- Profiles: V-board (for 90-degree edges), round/curved profiles (for coil OD/ID protection).

-

Interleaving Materials:

- Purpose: Placed between layers of a coil (during winding) or between stacked coils to prevent surface-to-surface abrasion, sticking, or transfer of contaminants.

- Types:

- Paper: Kraft paper, VCI paper, creped paper.

- Plastic Film: PE film, sometimes with non-stick properties.

- Foam: Thin foam sheets for cushioning and separation.

-

Dunnage and Palletization:

- Coil Pallets/Skids: Specially designed platforms to support the coil’s weight and shape, often with cradles or saddles. Materials include wood (ISPM 15 compliant for export), engineered wood, steel, or heavy-duty plastic.

- Wooden Dunnage: Blocks, battens, or lumber used to secure coils on pallets, separate stacked coils, or create a stable base within crates.

- Crates/Boxes: Fully enclosed wooden or heavy-duty corrugated boxes for maximum protection, especially for high-value or easily damaged coils.

-

Anti-Skid / Non-Slip Materials:

- Purpose: Sheets or coatings applied to pallet tops or between layers of stacked items (coils or boxes) to increase friction and prevent load shifting during transit. Materials include rubberized sheets or specially coated papers.

The careful selection and correct application of these materials are fundamental to a successful coil packing strategy. Buyers should discuss material specifications with their line provider to ensure compatibility with the machinery and optimal protection for their specific coil products.

Understanding Process & Quality Control Terminology in Coil Packing

The smooth operation of a coil packing line and the final quality of the packed product hinge on well-defined processes and robust quality control. Terms in this area can seem abstract, yet they directly impact your bottom line. Failing to grasp these concepts can lead to unclear expectations and underperforming lines.

Process and quality control terminology in coil packing encompasses metrics like cycle time (time to pack one coil), throughput (coils packed per unit time), OEE (Overall Equipment Effectiveness), pack integrity (ensuring the package is secure and undamaged), tension control (for strapping/wrapping), seal/weld strength (for straps), material coverage, and adherence to safety guarding standards. Mastering these terms allows buyers to critically assess line performance, reliability, and the protective capabilities of the packaging.

Key Performance Indicators (KPIs) and Quality Checks in Coil Packing Lines

Beyond the physical machinery and materials, a coil packing line’s success is measured by its performance and the consistent quality of its output. Buyers must be familiar with the terminology used to define and quantify these aspects to effectively evaluate proposals and ensure long-term operational excellence.

H3: Line Performance Metrics – Gauging Efficiency

These metrics help quantify how well and how fast your packing line operates.

-

Cycle Time:

- Definition: The total time taken to complete one full packing sequence for a single coil, from the moment it enters the line (or a specific station) until it exits as a fully packed unit. This is a crucial metric for determining the line’s maximum output capacity.

- Factors Affecting Cycle Time: Coil dimensions (ID, OD, width, weight), number of straps, layers of wrapping material, machine speeds (conveyors, strapping heads, wrapping arms/shuttles), automation level, and efficiency of material handling.

- Measurement: Typically measured in seconds or minutes per coil. It’s vital to understand if the quoted cycle time is for an average coil, a best-case scenario, or a specific coil an.

-

Throughput (or Production Rate):

- Definition: The number of coils processed or packed by the line within a specific period (e.g., coils per hour, coils per shift, coils per day).

- Relationship to Cycle Time: Throughput is inversely related to cycle time (Throughput ≈ 1 / Cycle Time, adjusted for units). For example, a cycle time of 2 minutes per coil theoretically allows for 30 coils per hour.

- Real-World Throughput: Actual throughput will always be less than theoretical maximum due to factors like material changes, minor stoppages, and planned maintenance.

-

Uptime and Downtime:

- Uptime: The percentage or amount of time the packing line is operational and producing packed coils as intended.

- Downtime: The percentage or amount of time the line is not operational. Downtime can be:

- Planned: Scheduled maintenance, material roll changes, product changeovers.

- Unplanned: Equipment breakdowns, material jams, quality issues requiring line stoppage.

- Importance: High uptime is critical for meeting production schedules. Understanding common causes of downtime helps in planning preventive maintenance and spare parts inventory.

-

OEE (Overall Equipment Effectiveness):

- Definition: A comprehensive metric that measures manufacturing productivity. It identifies the percentage of manufacturing time that is truly productive.

- Calculation: OEE = Availability × Performance × Quality

- Availability: (Actual Run Time / Planned Production Time). Accounts for unplanned and planned stops.

- Performance: (Ideal Cycle Time × Total Coils Produced) / Actual Run Time. Accounts for slow cycles and small stops.

- Quality: (Good Coils Produced / Total Coils Produced). Accounts for defective packs that need rework or are scrapped.

- Significance: A world-class OEE is typically 85% or higher. For coil packing lines, tracking OEE helps identify bottlenecks and areas for improvement in efficiency and quality.

H3: Automation and Control System Terminology

Modern coil packing lines rely heavily on automation for efficiency and consistency.

- PLC (Programmable Logic Controller): The industrial computer brain of the packing line. It controls the sequence of operations, motor speeds, sensor inputs, and actuator outputs based on pre-programmed logic.

- HMI (Human-Machine Interface): A graphical interface (often a touchscreen panel) that allows operators to monitor the line’s status, adjust parameters, receive alarms, and perform diagnostics. A user-friendly HMI is crucial for efficient operation and troubleshooting.

- SCADA (Supervisory Control and Data Acquisition): For more complex or integrated lines, SCADA systems provide a higher-level overview, allowing for centralized monitoring, control, and data logging of multiple PLCs or an entire plant floor.

- Sensor Technology: Various sensors are used for:

- Coil Detection & Positioning: Photoelectric sensors, inductive proximity sensors, or laser sensors to detect coil presence, measure dimensions (ID/OD), and ensure correct positioning at each station.

- Material Monitoring: Sensors to detect low levels of strapping, film, or paper, or to identify material breaks.

- Safety: Light curtains, door interlock switches, emergency stop buttons.

- Quality Control: Vision systems can be used to inspect strap placement, wrap coverage, or label application.

H3: Quality Control Checks and Terminology

Ensuring each packed coil meets predefined standards is vital to prevent damage and customer complaints.

- Pack Integrity: A general term referring to the overall soundness of the final package. This includes ensuring straps are tight, wrapping is complete and secure, and any protective elements are correctly applied.

- Tension Control (Strapping & Wrapping):

- Strapping Tension: Applying the correct amount of force to the strap. Too little tension results in a loose, unstable pack. Too much tension can damage the coil (especially soft metals or thin edges) or the strap itself. Measured in N, kgf, or lbs.

- Wrapping Film Tension/Pre-stretch: Crucial for ensuring the stretch film applies adequate containment force without over-compressing or damaging the coil.

- Seal/Weld Strength (Strapping): The joint created by the strapping head (e.g., friction weld for PET, notch for steel) must be strong enough to withstand handling stresses. Typically specified as a percentage of the strap’s break strength (e.g., 80% joint efficiency).

- Material Coverage (Wrapping): Ensuring the wrapping material (film or paper) completely covers the designated surfaces of the coil, with appropriate overlap between layers to prevent gaps.

- Labeling and Identification Accuracy: Verifying that all labels (product ID, shipping, safety) are correctly applied, legible, and that barcodes/RFID tags are scannable.

- Safety Guarding and Interlocks: Compliance with safety standards (e.g., OSHA in the US, CE marking in Europe) is a quality aspect in itself. Guarding must prevent access to hazardous areas during operation, and interlocks must stop machinery if guards are opened.

A typical coil packing quality checklist might include:

| Quality Checkpoint | Parameter Checked | Method of Checking | Acceptance Criteria (Example) |

|---|---|---|---|

| Strapping Application | Number of straps, strap placement, strap tension, seal/weld integrity. | Visual, manual check, tension gauge, seal inspection. | Correct number and position, tension within ±10% of spec, seal >80% break strength. |

| Wrapping Quality | Film/paper coverage, overlap percentage, film tail securement, tension. | Visual, manual check (pull test for film). | 100% coverage, min 50% overlap, no loose tails, adequate containment. |

| VCI Effectiveness (if used) | Correct VCI material for metal type, sufficient material applied, package sealed. | Visual, documentation review. | VCI active, no exposed metal if specified, pack airtight if required. |

| Edge/Corner Protection | Correct type and placement of protectors. | Visual. | Protectors cover all strap contact points, no strap-to-coil contact. |

| Package Stability & Integrity | Overall pack tightness, no coil movement within package, no visible damage. | Manual push/pull test, visual. | Pack is firm, coil is secure, no dents or tears in packaging. |

| Labeling & Marking | Correct labels, accurate information, legibility, barcode readability. | Visual, barcode scanner. | All labels present and correct, barcodes scan on first attempt. |

By understanding these process and quality control terms, buyers can better specify their performance expectations, ask pertinent questions during vendor discussions, and ensure the coil packing line they invest in will consistently meet their production and quality demands.

Essential Commercial and Logistical Terms for Coil Packing Line Buyers

Beyond the technical specifications of machinery and materials, purchasing a coil packing line involves navigating a landscape of commercial and logistical terms. A firm grasp of this vocabulary is vital for smooth project execution, from initial contract to final commissioning and beyond. These terms define responsibilities, timelines, and financial implications that can significantly impact the overall success of your investment.

For buyers of coil packing lines, essential commercial and logistical terms include FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) to verify equipment performance pre- and post-installation, ROI (Return on Investment) and TCO (Total Cost of Ownership) for financial viability assessment, lead time for project scheduling, Incoterms for defining shipping responsibilities in international deals, and warranty/SLA (Service Level Agreement) terms for post-purchase support. Understanding these ensures clear contractual agreements and sound financial planning. This foundational knowledge helps in mitigating risks, managing expectations, and ensuring the coil packing line project is delivered on time, within budget, and to the required performance standards.

-

FAT (Factory Acceptance Test):

- Definition: A crucial pre-shipment verification process conducted at the manufacturer’s facility. The buyer (or their representative) witnesses the assembled coil packing line (or key modules) operating with test materials (ideally similar to the buyer’s actual coils).

- Purpose: To confirm that the equipment has been built according to the agreed-upon specifications, functions correctly, and meets preliminary performance targets before it’s dismantled and shipped to the buyer’s site. This is the primary opportunity to identify and rectify major issues before shipment, saving significant time and cost later.

- Typical Checks: Dimensional accuracy, component verification against parts lists, basic machine movements, control system functionality (PLC/HMI responses), safety interlock operability, and often a short run with test coils to check cycle times and basic pack quality.

- Buyer’s Role: Prepare a detailed FAT protocol or checklist (often collaboratively with the supplier), actively participate in the testing, document all observations and deviations, and formally sign off (or list deficiencies) before authorizing shipment.

-

SAT (Site Acceptance Test):

- Definition: A post-installation verification process conducted at the buyer’s facility after the coil packing line has been installed and commissioned.

- Purpose: To confirm that the equipment, now in its operational environment, performs according to the contractual specifications, including throughput, pack quality, uptime, and integration with any existing upstream or downstream systems. This is the final sign-off before full production handover.

- Typical Checks: Re-verification of FAT items, sustained production runs (e.g., for several hours or a full shift), testing with actual production coils and consumables, confirmation of cycle times and throughput under real-world conditions, pack integrity checks, operator and maintenance personnel training verification, and final documentation review.

- Key Performance Indicators (KPIs): Specific, measurable targets for OEE, cycle time, changeover time, and defect rates are often part of the SAT criteria.

-

ROI (Return on Investment):

- Definition: A financial metric used to evaluate the profitability of an investment. For a coil packing line, it measures the financial benefits (e.g., labor savings, reduced material waste, decreased product damage, increased throughput leading to higher sales) relative to its cost.

- Simple Calculation: ROI (%) = (Net Profit from Investment / Cost of Investment) × 100.

- Considerations: Buyers should work with suppliers to realistically estimate potential savings and factor in all associated costs (not just the machine price) to project a meaningful ROI and payback period.

-

TCO (Total Cost of Ownership):

- Definition: A comprehensive financial estimate intended to help buyers determine the direct and indirect costs of a product or system over its entire lifespan.

- Components:

- Initial Purchase Price: Cost of the machinery.

- Installation & Commissioning Costs: Site preparation, rigging, utility connections, supplier’s installation team expenses.

- Training Costs: For operators and maintenance staff.

- Consumable Costs: Strapping, film, paper, labels, energy (electricity, compressed air).

- Maintenance & Repair Costs: Scheduled preventive maintenance, spare parts, labor for repairs.

- Downtime Costs: Lost production during planned and unplanned stoppages.

- Upgrade/Obsolescence Costs: Potential future modifications or replacement.

- Disposal Costs: At end-of-life.

- Importance: A lower purchase price doesn’t always mean a lower TCO. Reliability, efficiency, and a good maintenance program are key to minimizing long-term costs.

-

Lead Time:

- Definition: The duration from the official placement of the purchase order (and often, receipt of down payment) to the point when the coil packing line is ready for FAT, or delivered to the buyer’s site, or fully commissioned. The exact milestone should be clearly defined in the contract.

- Factors: Complexity of the line, degree of customization, supplier’s current order backlog, availability of key components (especially PLCs, servo motors, and specialized heads).

- Impact: Critical for overall project scheduling, facility preparation, and coordinating with other related installations or production changes.

-

Incoterms® (International Commercial Terms):

- Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clearly communicate the tasks, costs, and risks associated with the transportation and delivery of goods.

- Examples relevant to machinery:

- EXW (Ex Works): Buyer bears all costs and risks from the seller’s factory door.

- FOB (Free on Board): Seller is responsible for costs and risks until goods are loaded onto the shipping vessel/aircraft at a named port/airport.

- CIF (Cost, Insurance, and Freight): Seller pays for cost and freight to bring the goods to the port of destination, and also procures marine insurance against the buyer’s risk of loss or damage.

- DDP (Delivered Duty Paid): Seller is responsible for delivering the goods to the named place in the country of the buyer, and pays all costs in bringing the goods to the destination including import duties and taxes.

- Importance: Crucial for international purchases to avoid misunderstandings regarding shipping, insurance, and customs clearance responsibilities and costs.

-

Warranty and Service Level Agreements (SLAs):

- Warranty: The supplier’s guarantee regarding the quality and performance of the equipment for a specified period. Details what is covered (parts, labor), exclusions, and the process for making claims.

- SLA: A contractual agreement defining the level of service the supplier will provide post-installation. This can include guaranteed response times for service calls, availability of technical support (phone, remote, on-site), spare parts availability, and provisions for software updates or preventive maintenance visits.

-

Spare Parts Packages:

- Initial Spares: A set of recommended spare parts to have on-hand at the time of commissioning. Typically includes common wear items or critical components that could cause significant downtime.

- Ongoing Spares Strategy: Plan for maintaining an inventory of critical spares based on supplier recommendations and your own operational risk assessment.

-

Customization vs. Standard Modules:

- Standard Modules: Pre-engineered and tested components offer reliability and often shorter lead times and lower costs.

- Customization: Tailoring the line to specific, unique coil sizes, handling requirements, or plant layouts. Increases engineering effort, cost, and potentially lead time, but may be necessary for optimal performance in certain applications.

A thorough understanding of these commercial and logistical terms arms buyers with the necessary knowledge to negotiate fair contracts, manage project timelines effectively, make sound financial evaluations, and ensure smooth international transactions, ultimately leading to a more successful and less stressful coil packing line acquisition.

Conclusion

Navigating the intricate landscape of coil packing lines requires more than just identifying potential machinery; it demands a clear and comprehensive understanding of the specialized terminology that defines this industry. From the core components of the machinery itself, through the nuances of protective materials, to the critical metrics of process efficiency and quality control, and finally the commercial and logistical framework of the purchase – each term holds significance. A well-informed buyer is an empowered buyer, capable of asking the right questions, accurately comparing proposals, and investing in a system that truly aligns with their operational needs and strategic goals. This glossary aims to be that empowering tool, ensuring that your journey into acquiring or upgrading a coil packing line is built on a solid foundation of knowledge. Remember, for specific applications such as those involving thinner materials, a deeper look into wire packing automation can provide further insights into achieving optimal pack integrity and efficiency. Ultimately, proficiency in Packing Terminology is the cornerstone of a wise and successful capital investment.