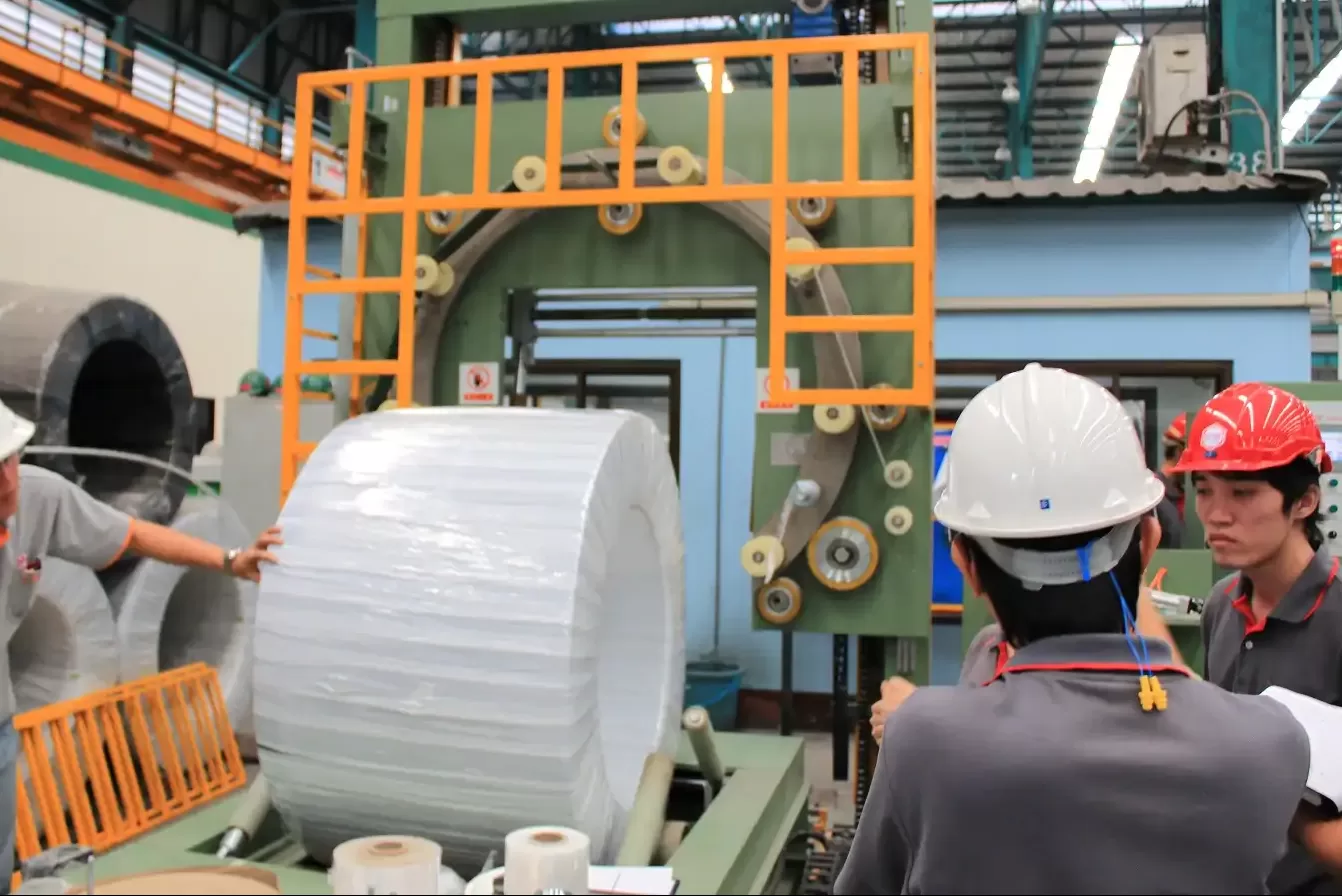

Struggling to efficiently package a diverse range of coil sizes and weights? Manual adjustments and ill-fitting systems can cripple productivity and increase product damage. It’s time for a solution that adapts to your needs, not the other way around, ensuring every coil, regardless of its specifications, is perfectly packed.

Tailoring your coil packing line involves designing and configuring machinery with adjustable components, robust build quality, and intelligent automation. This ensures the system can seamlessly handle varying coil diameters, widths, and weights by modifying parameters for conveying, wrapping, strapping, and stacking operations, optimizing protection and efficiency for each specific coil.

The journey to a perfectly optimized coil packing line might seem complex, but understanding the core principles of customization unlocks significant operational advantages. From initial coil handling to final stacking, every stage can be fine-tuned. This article will delve into the critical aspects of tailoring your line, ensuring you can confidently process any coil that comes your way, boosting throughput and safeguarding your valuable products.

Understanding Coil Variability: The Foundation of Tailored Packing

Handling coils of mismatched sizes and weights on a fixed packing line? This leads to inefficient changeovers, potential equipment strain, and compromised package integrity. A one-size-fits-all approach simply doesn’t cut it in modern coil processing. You need a system built for adaptability from the ground up.

Understanding coil variability is paramount because it directly dictates the design and operational parameters of the packing line. Key considerations include the minimum and maximum inner diameter (ID), outer diameter (OD), width, and weight of the coils. For instance, a line designed for narrow, light aluminum coils will differ significantly from one handling wide, heavy steel coils. Material type (steel, aluminum, copper, etc.) also influences handling and protection needs. Accurately defining this range allows engineers to select appropriately sized conveyors, design adjustable wrapping and strapping heads, ensure sufficient structural integrity in handling components like turnstiles and down-enders, and program PLCs with recipes for diverse product specifications. This comprehensive understanding prevents bottlenecks, minimizes damage, and maximizes the line’s efficiency and return on investment, ensuring it’s truly tailored to the production environment.**

Deep Dive: Analyzing Coil Specifications for Optimal Line Design

To truly tailor a coil packing line, a meticulous analysis of coil specifications is not just recommended—it’s essential. This goes beyond just knowing the maximums; it involves understanding the full spectrum of products the line will encounter and how their characteristics interact with packaging machinery.

Coil Dimensions: The Geometric Challenge

The physical dimensions of the coils are the most immediate factors influencing line design.

- Inner Diameter (ID): This impacts the design of coil cars, turnstile arms, upenders/down-enders, and particularly the eye-through strapping and wrapping mechanisms. A smaller ID might require more compact machinery or specialized tools to pass through the eye, while a larger ID allows for more robust solutions. Lines must accommodate the narrowest ID without collision and the widest without instability.

- Outer Diameter (OD): The OD dictates the scale of wrapping machines (shuttle size for orbital wrappers), the reach of strapping heads, and the capacity of stacking systems. Larger ODs mean more packaging material per coil and require machinery with sufficient clearance and travel. The conveyor system and centering devices must also be able to handle the full range of ODs.

- Width: Coil width is a critical factor for conveyor design, strapping machine placement (ensuring straps are correctly positioned relative to the coil edge), and the application of edge protectors. Wider coils may require multiple strapping heads or wider wrapping film. For slit coils, a packing line often handles a diverse array of widths from a single master coil.

The table below illustrates how varying dimensions for different coil types can influence packing line considerations:

| Coil Type | Typical ID (mm) | Typical OD (mm) | Typical Width (mm) | Max Weight (kg) | Key Packing Line Considerations |

|---|---|---|---|---|---|

| Slit Steel | 508 – 610 | 800 – 1800 | 20 – 600 | 500 – 6000 | Robust strapping, turnstile capacity, down-ender for eye-to-sky, precise stacking for narrow coils. |

| Aluminum | 400 – 610 | 900 – 2000 | 30 – 2000 | 500 – 5000 | Gentle handling, protective wrapping (VCI/Paper), non-marking conveyors, precise tension control. |

| Copper | 300 – 508 | 600 – 1200 | 10 – 400 | 200 – 3000 | High surface protection, interleaved paper options, secure but non-damaging strapping. |

| Wire Coils | Varies Greatly | Varies Greatly | Varies Greatly | 100 – 2500 | Compacting before strapping, eye-vertical or horizontal packing, diverse wrapping needs. |

| Pipe Coils/Hose | Varies | Varies | Varies | Varies | Often lighter, requires coiling machine integration, specialized wrapping to maintain coil shape. |

Coil Weight: The Structural Imperative

Coil weight directly impacts the structural design of every load-bearing component.

- Turnstiles must have arms capable of supporting the heaviest coils without deflection.

- Coil cars and down-enders need robust hydraulic or electro-mechanical systems.

- Conveyor rollers, chains, and frames must be rated for the maximum load.

- Stacking systems, especially gantry or robotic arms, require precise engineering to lift and place heavy coils safely and accurately.

Over-specifying for weight can lead to unnecessary costs, but under-specifying is a recipe for failure, safety hazards, and premature wear.

Material Properties and Surface Sensitivity

Beyond dimensions and weight, the coil material itself plays a crucial role:

- Steel Coils (Cold Rolled, Galvanized, Stainless): Often require robust strapping (steel or high-tensile PET) and can benefit from VCI paper or film for corrosion protection. Surface quality can be critical for stainless or coated steels.

- Aluminum Coils: Softer and more prone to scratching or deformation. Require gentler handling, potentially non-marking conveyor surfaces, and protective interleaving or softer wrapping materials. Strapping tension must be carefully controlled.

- Copper Coils: Highly sensitive to oxidation and surface damage. Often require full protective wrapping, including VCI materials and potentially crepe paper for moisture absorption.

Understanding these nuances ensures that the packing line not only handles the coil physically but also preserves its quality. This involves selecting appropriate packaging materials and designing machinery that applies them correctly without causing damage. The ability to switch between, for example, VCI film for steel and PE film with crepe paper for copper, within the same line, is a hallmark of a truly tailored system.

Core Machinery Adaptations: Building Versatility into Your Line

Are your current machines struggling to keep up with the variety of coils your facility processes? Generic equipment often means compromises, leading to bottlenecks or subpar packaging. To achieve true efficiency, your line’s core components must be inherently adaptable.

Core machinery adaptations involve equipping turnstiles, down-enders, wrapping machines, strapping units, and stackers with adjustable mechanisms. This includes features like variable-speed conveyors, reconfigurable turnstile arms, wrapping shuttles that accommodate diverse coil diameters, strapping heads with programmable tension and positioning for different coil widths, and stackers with adaptable grippers or platforms. These modifications ensure optimal performance across a spectrum of coil dimensions and weights.**

Engineering Flexibility: Core Components and Their Customization

A truly adaptable coil packing line isn’t just a collection of machines; it’s an integrated system where each core component is engineered for flexibility. The goal is to handle the full spectrum of specified coil sizes and weights without significant manual intervention or lengthy changeover times.

1. Turnstiles and Coil Cars:

These are often the entry points for coils into the packing line.

- Adaptability: Turnstiles need arms that can securely hold coils of varying IDs and weights. For instance, a 4-arm turnstile might have each arm rated for 10T, 15T, or more, depending on the heaviest coils. The spacing and design of these arms must prevent damage to the coil’s inner wraps. Coil cars, used for transferring coils to the turnstile or other stations, must have adjustable saddles or supports to accommodate different ODs and widths, ensuring stable transport. Some systems allow for automatic adjustment based on pre-programmed coil data.

2. Down-enders / Tilters:

Essential for orienting coils from eye-to-sky (vertical ID) to eye-to-horizon (horizontal ID) or vice versa, depending on the packing process.

- Adaptability: These units must be robust enough for the heaviest coils and versatile enough for various diameters. The cradles or platforms need to support the coil securely during the tilting motion. For lines handling a wide OD range, the tilting mechanism’s geometry must ensure smooth operation without the coil slipping or binding. Speed control during tilting is also crucial, especially for heavier or more delicate coils.

3. Wrapping Machines (Orbital and Through-Eye):

These machines apply protective layers like stretch film, VCI paper, or HDPE.

- Adaptability:

- Orbital Wrappers: The ring or shuttle carrying the film roll must be large enough for the maximum coil OD. Modern machines offer adjustable film overlap, variable rotation speed, and programmable wrapping patterns (e.g., full wrap, eye-only, banded wrap). Some can automatically adjust the number of film layers based on coil size or protection requirements. Automated film roll changing devices (ARC) are a key feature for continuous operation with different materials or when rolls deplete.

- Through-Eye Wrappers (TEW): Critical for moisture protection, these machines wrap material through the coil’s eye. The key adaptation is the ability to handle various ID sizes and apply materials like crepe paper and PE film. The "arm" or mechanism feeding the material through the eye must be slender yet strong. The tension control for both paper and film is vital to ensure an airtight package without damaging the coil.

4. Strapping Machines:

These secure the coil or the packed coil, using steel or PET straps.

- Adaptability: Strapping heads must be able to apply straps radially (through the eye) and/or circumferentially.

- Placement: Machines can feature single or multiple heads (e.g., dual-head or quad-head radial strappers) that can be positioned automatically based on coil width to apply the required number of straps at precise locations.

- Tension: Programmable strap tension is crucial. Steel coils might require high tension, while softer aluminum or delicate copper coils need significantly less to prevent edge damage or deformation.

- Strap Type: Some machines can be configured to handle different strap widths and materials (e.g., 19mm PET, 32mm steel) with minimal changeover, or even feature interchangeable heads.

- Eye Size: For through-eye strapping, the mechanism must navigate the smallest ID effectively.

5. Stacking and Palletizing Systems:

The final stage, preparing coils for storage or shipment.

- Adaptability:

- Gantry Systems/Robots: These often use electro-permanent magnets, vacuum lifters, or mechanical grippers. The lifting mechanism must be adjustable or equipped with tools to handle varying coil IDs, ODs, and weights. For example, magnets can be configured for different coil face sizes, and grippers can adjust their span.

- Carousel/Linear Stations: These systems present pallets or skids for stacking. The stations themselves might need to accommodate different pallet sizes. The control system should allow for pre-programmed stacking patterns based on coil dimensions and customer requirements (e.g., single stack, pyramid stack, or specific orientations on a pallet).

- Timber/Pallet Feeders: Automated systems that feed wooden pallets, skids, or dunnage must be able to handle variations in these base materials if the line is to be truly flexible.

By thoughtfully engineering these core components with adjustability and robust design, manufacturers can create coil packing lines that are not just automated, but also intelligently adaptive to the diverse and evolving needs of their production.

Intelligent Automation: The Key to Dynamic Coil Handling

Relying on manual settings for each coil variation? This archaic approach invites errors, extends downtime, and limits your line’s true potential. To master diverse coil B, you need a system that thinks and adjusts on the fly.

Intelligent automation uses Programmable Logic Controllers (PLCs), sensors, and Human-Machine Interfaces (HMIs) to dynamically adjust packing parameters. PLCs store recipes for different coil sizes and weights. Sensors detect coil dimensions in real-time, triggering the PLC to select the appropriate recipe, which then commands wrapping machines, strappers, and stackers to adjust settings like tension, speed, and material usage automatically for seamless, optimized processing.**

The Brains of the Operation: Leveraging Technology for Seamless Adjustments

In a modern, tailored coil packing line, intelligent automation serves as the central nervous system, orchestrating the mechanical components to handle a wide array of coil sizes and weights with precision and efficiency. This is achieved through a sophisticated interplay of PLCs, sensors, and HMIs, moving far beyond simple on/off commands.

Programmable Logic Controllers (PLCs): The Command Center

PLCs are the workhorses of industrial automation. In a coil packing line tailored for variability:

- Recipe Management: The most crucial function is storing and executing "recipes." Each recipe contains a unique set of parameters optimized for a specific coil type, size, or weight. This can include:

- Conveyor speeds for specific sections.

- Wrapping machine settings (film stretch percentage, number of wraps, rotation speed, shuttle height).

- Strapping machine parameters (strap tension, number of straps, strap positions – e.g., 2 radial, 1 circumferential).

- Stacking patterns and pallet type selection.

- Timing sequences for all integrated machinery.

Operators can select recipes via an HMI, or the system can choose them automatically based on data from upstream systems (like a slitting line’s production schedule) or sensor inputs.

- Sequential Control & Interlocking: PLCs ensure all operations occur in the correct sequence and that machines are interlocked for safety and process integrity. For example, a strapping machine won’t activate if a coil is not properly centered, or a conveyor won’t feed a coil if the next station isn’t ready.

- Data Logging & Diagnostics: Modern PLCs can log operational data (e.g., number of coils packed, cycle times, material consumption, fault occurrences). This is invaluable for performance monitoring, predictive maintenance, and quality control. Advanced diagnostics help pinpoint issues quickly, reducing downtime.

Sensors: The Eyes and Ears of the Line

Sensors provide the real-time feedback necessary for dynamic adjustments and safe operation.

- Photoelectric Sensors: Detect the presence or absence of coils at various points, triggering an action (e.g., start conveyor, stop wrapper). They can also be used for basic width or diameter detection by their an array.

- Laser Measurement Systems/Ultrasonic Sensors: Provide precise, non-contact measurement of coil ID, OD, and width. This data can be fed directly to the PLC to automatically select the correct packing recipe or make fine adjustments to machine settings, such as the start/stop points for wrapping or the exact positioning of straps.

- Inductive Proximity Sensors: Detect metallic objects, useful for confirming coil presence, positioning on coil cars, or ensuring components like strapping heads are in the correct home position.

- Encoders: Mounted on motors, they provide feedback on speed and position, crucial for precise control of conveyor movement, wrapping shuttle rotation, and robotic arm positioning.

- Load Cells/Weighing Systems: Integrated into conveyor sections or buffer stations, these measure the coil’s weight. This data can confirm coil identity against a manifest, be used for labeling, and ensure that downstream equipment like stackers are operating within their load limits.

Human-Machine Interface (HMI): The Operator’s Window

HMIs provide a user-friendly graphical interface for operators to monitor and control the packing line.

- Recipe Selection & Management: Operators can easily select, modify (with appropriate authorization), or create new packing recipes.

- Real-Time Monitoring: HMIs display the status of all machines, sensor readings, active alarms, and production data (e.g., coils per hour, current coil being processed).

- Alarm Indication & Troubleshooting: When a fault occurs, the HMI clearly indicates the location and nature of the problem, often providing troubleshooting guidance.

- Manual Control: Allows operators to manually control individual machine functions for maintenance or setup purposes.

- Multiple Language Support: Essential for global operations.

The seamless integration of these technologies creates a system that is not just automated but truly adaptive.

| Automation Feature | Core Technology Used | Key Benefit for Handling Diverse Coils | Impact on Efficiency & Quality |

|---|---|---|---|

| Automatic Coil Recognition | Laser Sensors, Vision Systems, RFID | Identifies incoming coil dimensions/type without manual input. | Reduces setup time, eliminates human error in selection. |

| Dynamic Recipe Selection | PLC, HMI, Database Integration | Automatically loads pre-set parameters for the identified coil. | Ensures optimal packing for every coil, consistency. |

| Real-Time Parameter Adjustment | PLC, Sensors (Laser, Encoders) | Fine-tunes machine settings (e.g., wrap tension) based on live feedback. | Optimizes material usage, prevents coil damage. |

| Automated Fault Diagnostics | PLC, HMI, Advanced Software | Pinpoints issues quickly, guiding operators to solutions. | Minimizes downtime, speeds up recovery. |

| Centralized Line Control | HMI, SCADA systems | Provides a single point of view and control for the entire line. | Simplifies operation, improves overall coordination. |

This intelligent automation transforms a potentially complex operation into a streamlined, efficient process capable of handling a vast range of coil specifications with minimal operator intervention and maximal output quality.

Integrating a Holistic System: From Slitter to Stacker for All Sizes

Is your coil packing line an isolated island in your production flow? To truly master varying coil sizes and weights, it must be part of a larger, seamlessly integrated ecosystem. This means looking beyond individual machines to the entire process, from the moment a coil is produced or slit, through every handling and packaging step, to its final stacking and dispatch. A holistic approach ensures that data flows smoothly, handovers are automated, and each auxiliary system contributes to the line’s overall adaptability.

Integrating a holistic system involves connecting the core packing machinery (wrappers, strappers) with upstream processes like slitting lines and downstream systems like automated stacking and warehousing. Key to this is the intelligent use of coil cars, turnstiles, down-enders, and conveyors that are themselves adaptable to different coil dimensions and weights. Automated weighing stations, labeling systems, and timber/pallet feeders must also be designed to handle the full product range. For instance, a slit coil produced by a slitting line can be automatically transferred by a coil car to a turnstile, then conveyed through weighing, eye-through strapping, wrapping, and finally to a gantry stacker that places it on a correctly sized pallet, all based on pre-programmed data for that specific coil’s size and weight. This level of integration minimizes manual handling, reduces errors, and ensures that the entire operation is optimized for the diversity of coils being processed.

This comprehensive integration begins with understanding the output from the slitting line or primary coil production. For slitting lines, this often means handling multiple "pups" or slit coils of varying widths and potentially ODs, all originating from a single master coil. The packing line must be prepared to receive these coils sequentially or in batches. A well-designed system uses coil cars or transfer arms to pick up slit coils, often identified by barcode scanners or data links with the slitting line’s Level 2 or Level 3 control system. This data transfer is crucial, providing the packing line’s PLC with the exact dimensions, weight, and customer-specific packaging requirements for each incoming coil before it even arrives.

Auxiliary systems play a vital role in tailoring the packing process for each unique coil:

- Weighing Stations: Integrated load cells provide accurate weight data for labeling, shipping documents, and quality control. The station must accommodate the largest and heaviest coils.

- Labeling Systems: Automated label printer-applicators apply identifying labels with bar codes, coil data, and customer information. The system must be able to adjust label placement for different coil ODs and widths.

- Timber/Plank Feeders: For coils stacked on wooden pallets or planks, these automated systems select and place the correct size and number of timbers based on the coil’s dimensions and weight. This ensures stable and secure stacking.

- Edge Protectors/ID & OD Protectors: Some lines incorporate automated application of cardboard or plastic protectors to prevent damage to coil edges or inner/outer wraps, especially for sensitive materials. These applicators must adjust to different diameters.

- Data Integration (MES/ERP): Connecting the packing line’s control system (often PLC-based with an HMI/SCADA overlay) to higher-level Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems allows for seamless data exchange. This means packing instructions can be downloaded directly, and packing confirmations, material usage, and quality data can be uploaded in real-time. This ensures that the packaging meets specific order requirements and provides valuable data for inventory management and production planning. For example, Case One for India’s Steel service centers specified a line capacity of 25-30 coils/hour handling slit coils with ID 508mm, OD 800-1400mm, width 40-500mm, and max weight 4000kg, featuring a 4-arm turnstile, downender, dual head radial eye strapping, film wrapping, and a gantry with magnets for stacking—all indicative of a highly integrated and adaptive system.

By viewing the coil packing line not as a standalone unit but as a critical, integrated node in the overall material flow, manufacturers can unlock significant efficiencies and truly tailor their operations to handle any coil size or weight with precision and speed.

Conclusion

Tailoring your coil packing line to diverse coil sizes and weights is an investment in efficiency, safety, and product quality. By focusing on adaptable core machinery, intelligent automation, and holistic system integration, manufacturers can transform a potential bottleneck into a streamlined, high-performance operation. Understanding your specific Coil Dimensions and weight ranges is the crucial first step in designing a system that meets your unique needs, ensuring every coil is packed perfectly, every time. For those looking to optimize their operations further, [exploring advanced coil handling solutions]() can provide even greater insights into maximizing productivity and achieving a swift return on investment in this critical area of manufacturing.