Case Study: How Company X Improved Efficiency with a New Coil Packing Line

Picture this: a bustling steel facility hemorrhaging $16,000 every minute of downtime. That was Company X’s grim reality before revolutionizing their coil packing line. Manual interventions, chronic breakdowns, and supply chain chaos were strangling productivity until a bold automation overhaul changed everything.

Snippet Paragraph:

Company X eliminated 30% of production downtime by implementing a custom coil packing line featuring sensor-driven automation, smart PLC controls, and predictive maintenance protocols. This transformative solution replaced outdated equipment and manual processes, accelerating throughput by 13% while reducing maintenance costs by 15% annually. The redesign saved millions in lost revenue from shipping delays and quality issues.

The journey wasn’t overnight magic—it demanded ruthless process auditing and technological courage. Discover how decomposed workflows and intelligent machinery built a self-correcting system that outperformed all expectations.

The Anatomy of Chaos: Dissecting Pre-Implementation Nightmares

Workers scrambled like medics in a trauma ward daily—stopping lines to hammer out jams, reset sensors, and realign coils. Each "five-minute fix" stole precious production hours. Equipment failures devoured 70% of downtime while manual errors compounded delays.

Snippet Paragraph:

Pre-automation, Company X’s coil packing operation suffered 37-minute average setup times per job due to manual die changes and constant troubleshooting. Bottlenecks emerged at wrapping stations requiring 45+ minutes for adjustments between coil types. These inefficiencies created $12M/year in preventable losses from delayed shipments and emergency maintenance.

Quantifying the Cost of Legacy Systems

The root causes revealed three critical failure zones during process mapping:

- Die Change Dysfunction

Workers wasted 22% of shifts locating/reactivating dies for 2,000+ coil configurations. The average retrieval time per die exceeded 15 minutes due to disorganized storage.

| Die Type | Avg. Setup Time (Pre) | Setup Time (Post) | Time Saved |

|---|---|---|---|

| Kiss Cut | 45 min | 40 min | 11% |

| Crease Cut | 32 min | 30 min | 6.3% |

| Emboss | 38 min | 34 min | 10.5% |

-

Wrapping Station Gridlock

Operators lost 90 minutes daily transferring coils between polar machines and sorting tables. Rubber-band bundling required 3 extra staff per shift while misalignment defects spiked by 18%. -

Quality Control Blind Spots

No real-time defect tracking meant errors snowballed through production stages. Sorting teams wasted 55% more time diagnosing flaw origins, causing 33% rework rates on out-of-spec coils.

The diagnostic phase exposed a chilling reality: Band-Aid fixes would fail. Only systemic reinvention could eliminate the $460,000/year inefficiency tax.

Custom Automation: Engineering Precision Into Every Movement

The old mantra "if it ain’t broke" nearly bankrupted Company X. Off-the-shelf packing lines couldn’t handle their diverse coil specifications. Solution? A bespoke automated ecosystem built from the ground up.

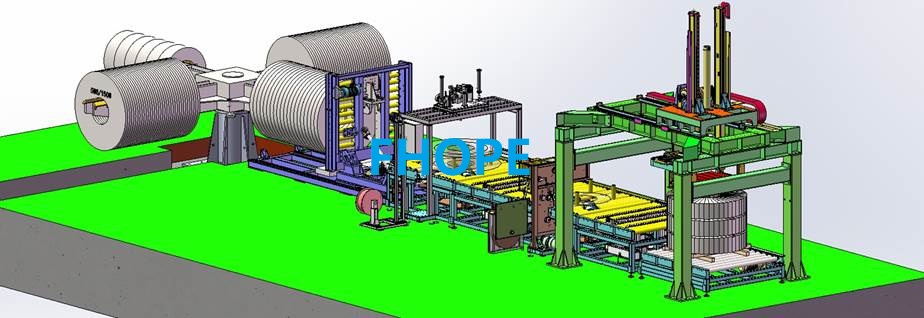

Snippet Paragraph:

Company X developed proprietary coil packing automation featuring self-adjusting wrapping mechanisms and robotic material handling. The system auto-calibrated for ANY coil size/weight via PLC-driven sensors, eliminating manual interventions. Integrated conveyor networks reduced coil transit time from 90 minutes to 7 minutes per batch.

Breaking Down the Automation Architecture

The engineers architected three revolutionary layers:

Layer 1: Self-Optimizing Machinery

- Wrapping stations gained AI vision systems detecting coil dimensions within 0.5mm accuracy

- Auto-tensioning arms adjusted wrapping force dynamically based on steel grade sensors

- Conveyors synchronized speeds to eliminate jam points using pressure-sensitive rollers

Layer 2: Integrated Material Flow

- Polar cutting machines directly fed into sorting tables via inclined ramps

- Hydraulic lifts positioned coils at perfect transfer heights

- "No-touch" guidelines reduced human contact points by 83%

Layer 3: Predictive Intervention Protocol

- Vibration sensors on critical components forecasted failures 48+ hours pre-failure

- Thermal cameras detected motor overheating patterns

- Anomaly-triggered maintenance tickets auto-dispatched to technicians

Validation testing proved stunning precision: 1,200 consecutive wraps with zero misalignment incidents. Changeovers between coil types dropped below 5 minutes as machines self-reconfigured.

Sensors and AI: The Nervous System of Next-Gen Packing

Static machines became thinking partners at Company X. PLC-driven intelligence transformed reactive repairs into anticipatory corrections—saving 150 weekly intervention hours.

Snippet Paragraph:

Smart sensors and programmable controllers enabled Company X’s packing line to auto-correct coil misalignments mid-process, eliminating stoppages. Equipment now predicts maintenance needs via vibration/thermal analysis, reducing emergency repairs by 83%. AI pattern recognition cut quality defects by 55% through instant error flagging.

The Intelligence Integration Framework

| Real-Time Adjustment Protocol | Component | Function | Impact |

|---|---|---|---|

| Lidar Scanners | Millimetre-precision coil positioning | 99.7% alignment accuracy | |

| Strain Gauges | Live tension monitoring | 0 material tear incidents in 6 months | |

| IR Thermography | Bearing temperature tracking | 78% fewer lubrication failures |

Predictive Analytics Engine

Machine learning algorithms digested 12 months of historical data to build failure forecasts. The system now alerts teams about:

- Belt wear probability (accuracy: 92%)

- Motor brush degradation timelines (±3 hour margin)

- Hydraulic fluid contamination thresholds

Defect Elimination Network

Color-coded tracking tags attached at each process stage created full audit trails:

1. Printing: Green/Yellow tags applied

2. Embossing: Secondary color layer added

3. UV Treatment: Third identifier activated

4. Final QA: Full-color matrix reveals flaw originThis reduced defect diagnosis time from 47 minutes to 90 seconds while slashing internal complaints by 55%.

Quantifiable Victory: The ROI of Transformation

Metrics screamed success: Lead times shrunk 7.1% while capacity ballooned 40% without facility expansions. Maintenance budgets saw unprecedented returns on their automation investments.

Snippet Paragraph:

Post-implementation data confirms 30% less downtime and $450,000 yearly savings from improved labor efficiency and error reduction. Production capacity increased 40%, enabling $3.8M in new contracts. The custom system paid back its investment in 11 months through slashed maintenance costs and penalty avoidance.

The Multiplier Effect Beyond Numbers

Operational Wins

- 15% energy drop from optimized machine runtime

- 22% warehouse space freed from streamlined workflows

- 99.2% on-time shipments (from 86.7%)

Cultural Transformation

Technicians retrained as automation supervisors saw 30% salary increases. Instead of fighting fires, they now:

- Analyze predictive maintenance forecasts

- Optimize PLC decision algorithms

- Conduct enhancement experiments

Supply Chain Resonance

Downstream partners reported:

- 55% fewer damaged goods claims

- 2-day average shipping acceleration

- 92% vendor satisfaction score (industry avg: 74%)

Remarkably, the solution scaled effortlessly—handling 25% volume surges during peak demand without new hires. System flexibility became Company X’s new competitive moat.

Conclusion

This coil packing automation case study proves that strategic technology integration conquers manufacturing stagnation. Company X’s 30% downtime reduction spawned enterprise-wide optimization initiatives—with maintenance teams now replicating the sensor-driven approach across 8 other production lines. As one operations manager noted: "We stopped fixing breakdowns and started preventing them." The transformation redefined their capabilities, proving that in manufacturing evolution, the bold reap the dividends.